By Tyler Bouchard 07/10/2025

What are the Benefits of Autonomous Process Control?

In today’s post, I want to talk about the different advantages and benefits of Autonomous Process Control (APC) and why it can be a game-changer for reindustrialization.

Let’s start with a quick definition of what APC is:

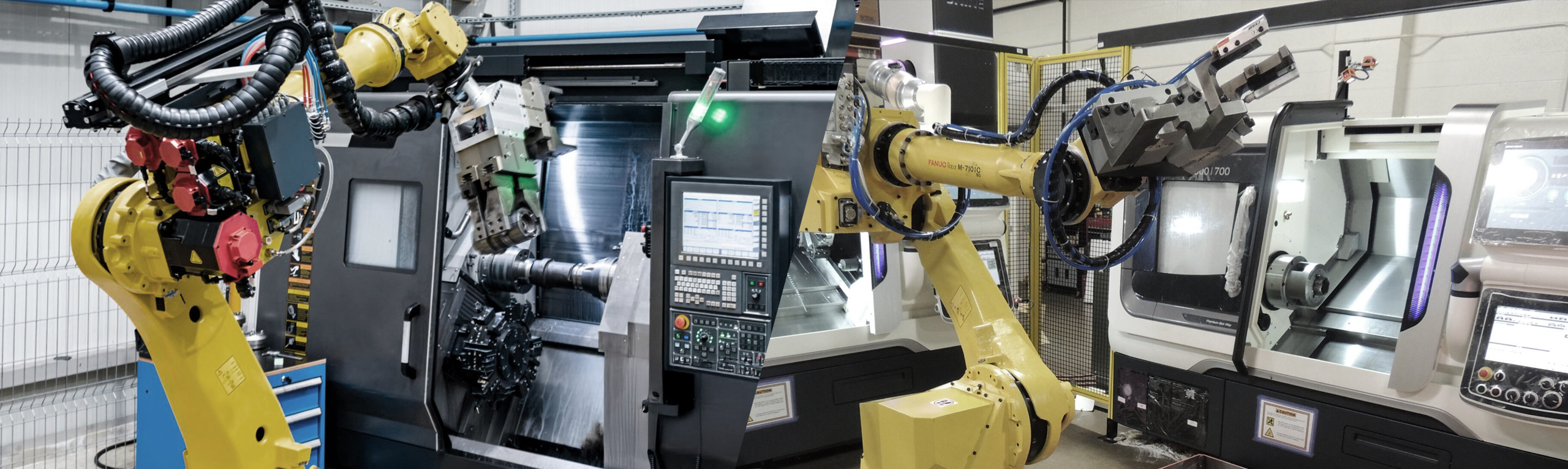

Autonomous Process Control creates closed-loop autonomy between your machines making products, your inspection & test systems reviewing their work, and your robots. APC makes real-time robotic production processing adjustments based on algorithmic calculations using the results from automated inspections and tests.

Basically, statistical process control limits for each of your product’s critical characteristics are digitally mapped in robotic production software to variables in your machine controller’s program. If tolerance drift or nonconformances occur, your robots autonomously correct the machine’s program.

This digital connection between building a product and checking its conformance to spec while operating unmanned – IOW operated by a robot – increases throughput, improves precision, and reduces waste, particularly in industries with stringent regulatory compliance.

Plus, the comprehensive set of data captured automatically creates a digital thread for regulatory compliance.

Using robotic production software to achieve APC represents a transformative approach for manufacturing repeatability with precision quality in any robot-enabled factory environment.

To learn more about APC you can download our paper on Autonomous Process Control using Robots and Automated Inspection in Manufacturing

The real question is what does that actually mean in your factory? Let’s break it down:

Greater Accuracy and Precision

APC reduces process variability by enabling robots to make real-time adjustments, resulting in more consistent part quality and tighter tolerances.

Defect Reduction

By identifying nonconformances earlier through in-process inspection, APC helps cut defect rates by more than 30%, leading to fewer bad parts and better customer satisfaction.

Yield Improvement

Through optimized processing, manufacturers can see production yields increase by 25-45% – depending on the process – which contributes directly to the bottomline.

Improved Quality Control

With fewer escapes and better data tracking, APC supports stronger compliance and traceability – especially important for industries like aerospace, defense, and life sciences.

Tighter Feedback Loops

APC provides closed-loop communication between inspections, machines, and robots, enabling immediate corrective actions that maintain quality in real time.

Reduced Scrap and Rework

Smarter adjustments mean less material waste and lower costs associated with reworking defective parts.

Lower Cost of Quality

By preventing issues before they snowball, APC reduces the overall Cost of Quality by 20% or more, improving margins across the board.

EBITDA Improvements

With higher productivity and fewer defects, businesses benefit from stronger profit per part and better EBITDA performance.

As your factory moves toward greater autonomy, APC isn’t just a ‘nice to have’ concept, it represents the foundational basis of your autonomous manufacturing efforts.

In other words, if you cannot make high quality products repeatably without human intervention, you will never achieve the “lights out” operations required for autonomous manufacturing.

If you want to understand the specifics of how to achieve APC with robots in your factories, you can get our white paper on APC implementation recommendations here.