Our Solution Supports

BASIC

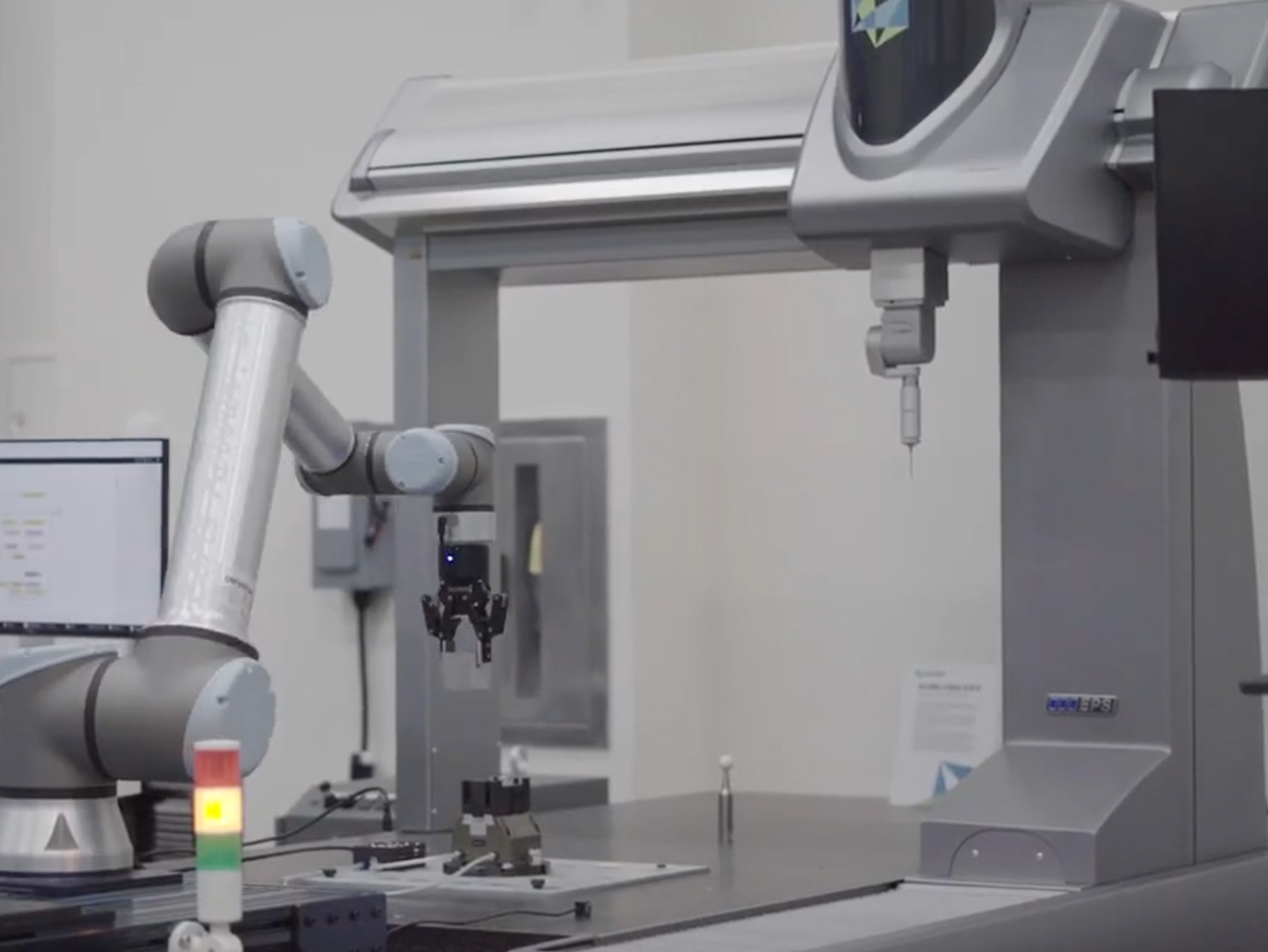

Robot Machine Tending

Robot + Single Machine

Load and Unload Parts

to Improve Unattended Operation

and Throughput

ADVANCED

Robot Machine Tending

Robot + Multi-Machine

Closed-loop Coordination Between

Two, Three, Five or More Machines

for Greater Capacity, Yield, and Margins

BASIC

Robot Machine Tending

Robot + Single Machine

Load and Unload Parts

to Improve Unattended Operation

and Throughput

ADVANCED

Robot Machine Tending

Robot + Multi-Machine

Closed-loop Coordination Between

Two, Three, Five or More Machines

for Greater Capacity, Yield, and Margins

Solution Install Options

Stationary /

Pedestral

Setups

Carts with

Trays &

Auto-Drawers

Robot

Multi-Machine

Layouts

Rail Systems

& Gantry

Configurations

Multi-Op

Cellular

Footprints

Stationary /

Pedestral

Setups

Stationary /

Pedestral

Setups

Stationary /

Pedestral

Setups

Stationary /

Pedestral

Setups

Stationary /

Pedestral

Setups

Our Customers

Complete guide to

Robotic Machine

Tending Projects

PDF DOWNLOAD

Everything you need to plan, implement and operate robotic machine tending at your factory

Processes & Operations

Stationary /

Pedestral

Setups

Stationary /

Pedestral

Setups

Stationary /

Pedestral

Setups

Stationary /

Pedestral

Setups

Stationary /

Pedestral

Setups

Additive Manufacturing

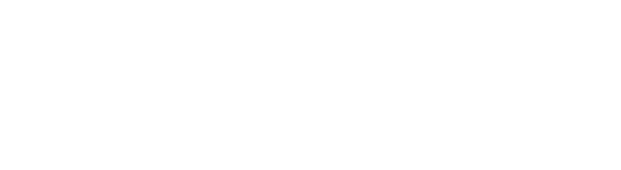

Laser Cutting

and Engraving

Machining

Centers

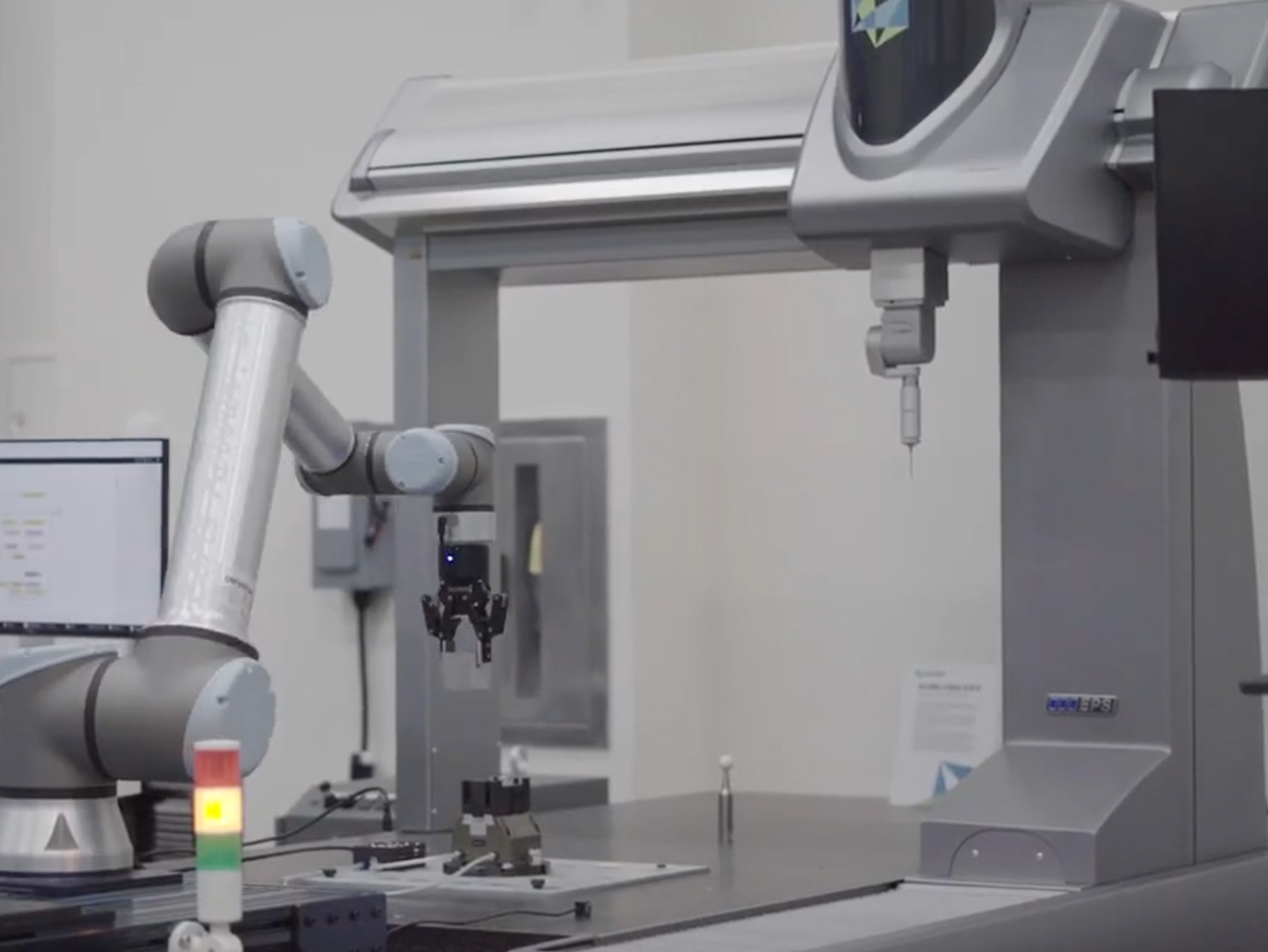

Quality

Inspection

& Testing

Production

Lines &

Assembly

Robot-enable all your machines & equipment

Turning Centers & Lathes

Horizontal

Vertical

Dual Spindle

Milling Machines

Pallet Changers

Multi-Axis Horizontal & Vertical

Swiss Lathes

Multi-Axis

Outfeed Inspection

Multi-Tasking Machines

Electrical Discharge Machines

CMM

PCB Testers

Laser Markers & Engraving

CNC Grinding

Deburring

Honing Machines

Injection Mold Machinery

Press Brakes

3D Printers / Additive

Drill & Tap Machines

Flexxbotics works with

all types of machines & equipment

- Compatibility with 1000+ makes & models of factory machinery

- Makes robots & cobots communicate with machines

- Enables many-to-many PLC interoperability

Include Additional Operations

- Washdown & Blow-off

- Deburring and surface finishing

- Unique Device Indentification (UDI) marking

Incorporate Automated Inspection

- Option to use automated inspection in-line

- Closed-loop feedback for real-time offset adjustments

- Reduce defects, avoid nonconformances, improve yields

More Part Type Capabilities

- Ability to handle a wide range of form factors, surfaces and materials

- From complex geometry parts and multi-part assemblies to simple stock parts

- Even parts with ISO 2768 and ISO 286 precision tolerances including Class III orthopedics & implants

Enable Multiple Operation Steps

- Multi-operation automated part fabrication

- Orchestrate multi-op process for multiple parts/SKUs across multiple machines

- Robot takes your parts from multi-step machining through post-processing, cleaning, and inspection

Unprecedented SKU Functionality

- Multi-SKU for High Volume / High Mix

- Supports both Line Clear or Non-Line Clear

- Bar code scanning automatically calculates part quantities across multiple machines

- Work Order changeovers detect order completion and update part properties for the next order in-feed

Expert Services & Support

- Business Objectives | Target Outcomes | ROI Justifications

- Requirements Definition | Solution Design | Component Selection

- Equipment Installation | Machine Connectivity | Robot Programming

- Safety & Risk Assessments | Factory and Site Acceptance

- On-site and Remote Support

Intelligent Recovery

Only Flexxbotics provides patent-pending technology to enable robots to auto-recover from non-safety related stops so unattended production continues without downtime

Breakthrough

Innovation

Inside Flexxbotics is our unique FlexxCORE™ technology which seamlessly connects and coordinates robots with factory equipment, IT Systems and people to deliver robot-driven manufacturing

This patent-pending low code software infrastructure enables robot+multi-machine interoperability to digitalize robotic production for next generation smart factory environments

White Paper

Autonomous Process Control in manufacturing

Blog

Robot Machine Tending Essentials

Learn More | Request a Demo

"*" indicates required fields

Flexxbotics values your privacy. Website terms and conditions.