Heavy Manufacturing

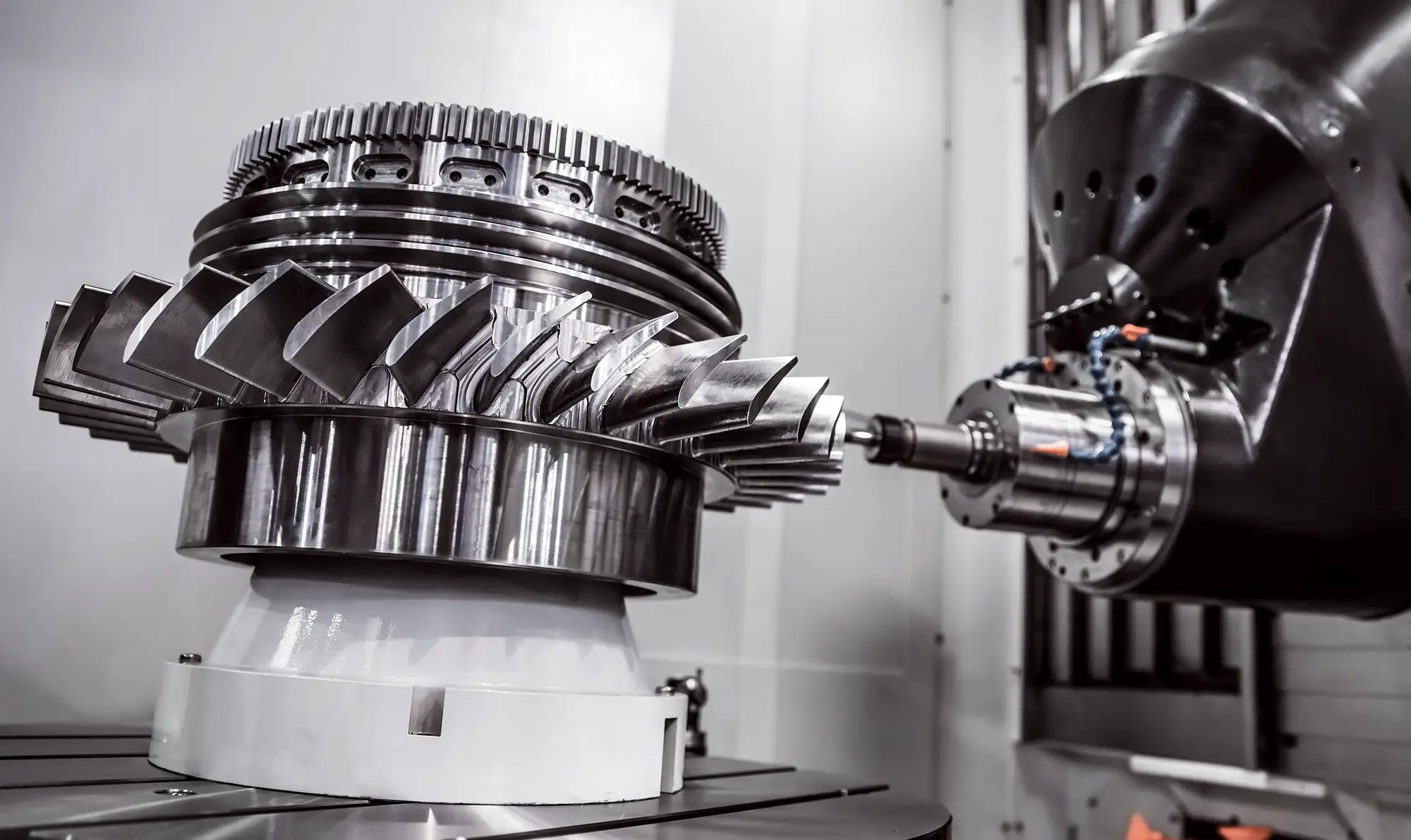

Robotic digitalization for precision manufacturing with tight tolerances from volume production to frequent changeover environments including ITAR parts and quality systems compliance

- Aerospace, Defense, and Space

- Automotive, Heavy Duty, and Transportation

- Industrial Products and Fabrication

High Tech

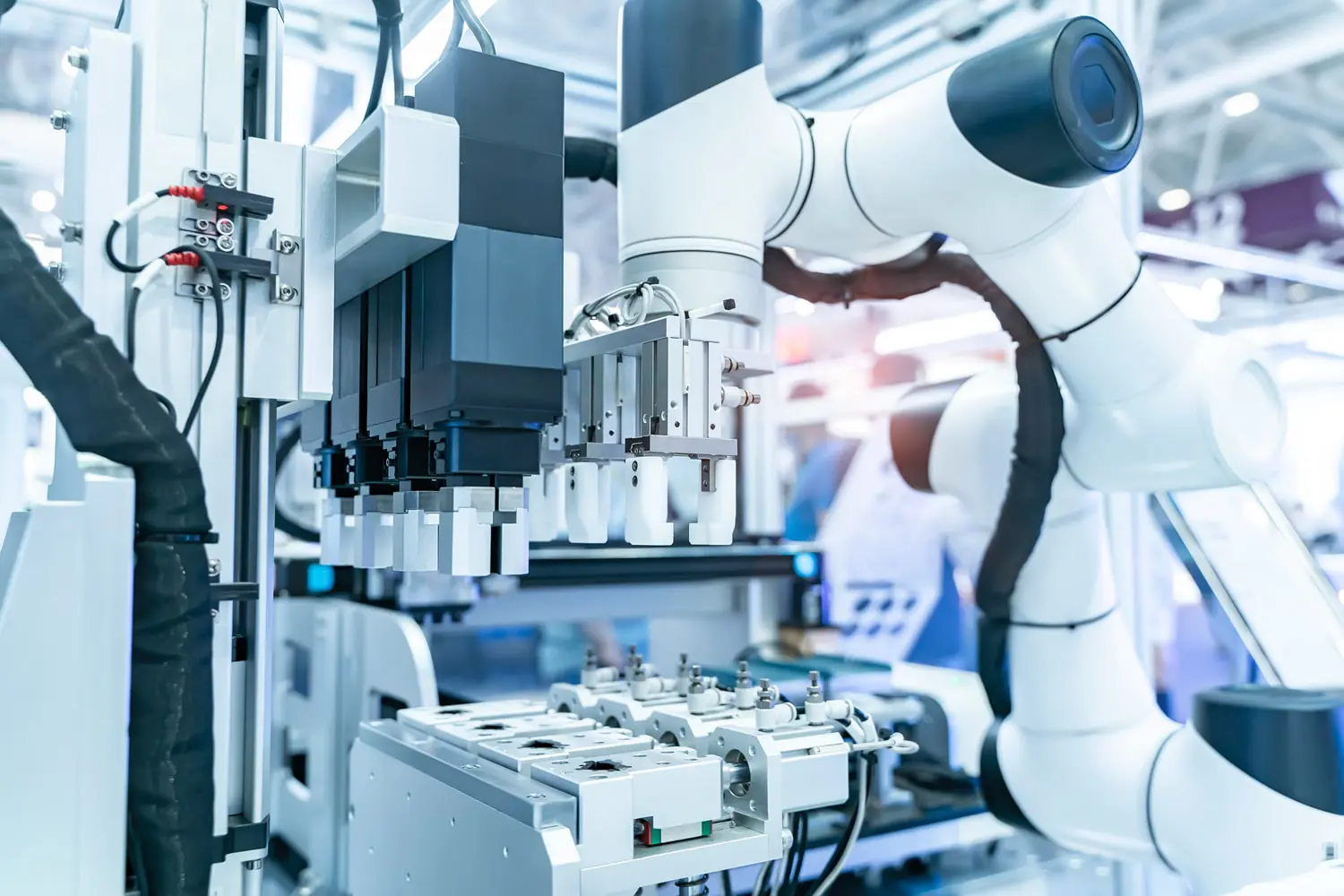

Robotic enablement of fab, assembly, and test equipment at scale for continuous operations with six sigma quality during lights out production

- Semiconductor Fab & Assembly

- Electronics Contract Manufacturing

- Batteries and Clean Tech

Life Sciences

Robot-enabled processes in clean room laboratories and production with FDA compliant QSR control & traceability for repeatable quality and greater throughput

- Medical Devices

- Pharmaceuticals

- Biotech

Our Customers

Value Delivered

Using Flexxbotics to transform robotic machine tending into robot-driven manufacturing your factory can achieve dramatic results

Increased Capacity, Efficiency Gains, Yield Improvements

with greater visibility, agility and compliance

20 : 1

MACHINE-TO-MAN RATIO

Contract Manufacturer

58.3%

CAPACITY INCREASE

Manufacturer

OVER 1 HOUR TO

LESS THAN 10 MINUTES

CHANGE OVER TIME REDUCTION

Machining Operation

With Flexxbotics we have achieved our 80% utilization goal in less than 90 days.”

Flexxbotics enabled us to quickly identify the root cause of our robot downtime issues and provided effective resolution to maximize our robot utilization and performance.”

We’re particularly impressed with Flexxbotics compatibility with all makes and models of machines in our factory enabling us to roll out automation across our workcells quickly and efficiently.”

CUSTOMER SUCCESS & HIGHLIGHTS

Robot-Driven Manufacturing Enables “Lights-Out” Production

Robot-Driven Manufacturing Achieves Autonomy in Medical Devices

Heckler & Koch USA Selects Flexxbotics for Robot-Driven Manufacturing