Flexxbotics Software makes your

factory automation solutions work

PLCs

Struggling to reduce integration

complexity and work arounds?

Machines

Trying to detect machine issues and

increase tool life or automate offsets?

Robots

Looking to install robots, manage

multiple cells, and optimize uptime?

MES / QMS

Stuck trying to connect machines to

MES & QMS or roll out cell integration?

SCADA

Working to capture more data from

machines or extend data monitoring?

What we do

Process Trend

Intelligence

Automated Manufacturing

Compliance

Factory AI Data

Acquisition

Robotic

Production

Flexxbotics makes automation work for you at scale

We’re combining our breakthrough software with state-of-the-art hardware and expert services to deliver unrivaled autonomy solutions

We make factory automation & robots talk to your machines and coordinate work for greater throughput, higher yields, and better margins

Manufacturing

- Aerospace, Defense, and Space

- Automotive and Heavy Duty

- Industrial Products and Fabrication

High Tech

- Semiconductor Fab & Assembly

- Electronics Manufacturing

- Batteries & Clean Tech

Life Sciences

- Medical Devices

- Pharmaceuticals

- Biotech

Our Customers

No more consultant customized science projects

Standardizing the most

complex autonomy challenges

- Process trend intelligence across a range of factory operations

- Automated manufacturing compliance and execution control

- Robotic production across heterogeneous factory equipment

- AI-ready data acquisition and contextualization across machines and systems

Our Difference

Powerful

Performance

Scalable

Secure

Flexible

Adaptable

Extensible

Agile

Open

Standards

Connectivity

Interoperable

Does your factory have common

automation issues?

- Are your automation cells idle more than running?

- Is work order / job changeover too complex & slow?

- Does unplanned downtime ruin your utilization and output?

Does your factory have common

automation issues?

- Are your automation cells idle more than running?

- Is work order / job changeover too complex & slow?

- Does unplanned downtime ruin your utilization and output?

Value Delivered

Increased Capacity, Efficiency Gains, Yield Improvements

with greater visibility, agility and compliance

58.3%

CAPACITY INCREASE

Global Diversified Manufacturer

OVER 1 HOUR TO

< 10 MINUTES

CHANGE OVER TIME REDUCTION

Medical Device Machining Operation

20 : 1

MACHINE-TO-LABOR RATIO

International Contract Manufacturer

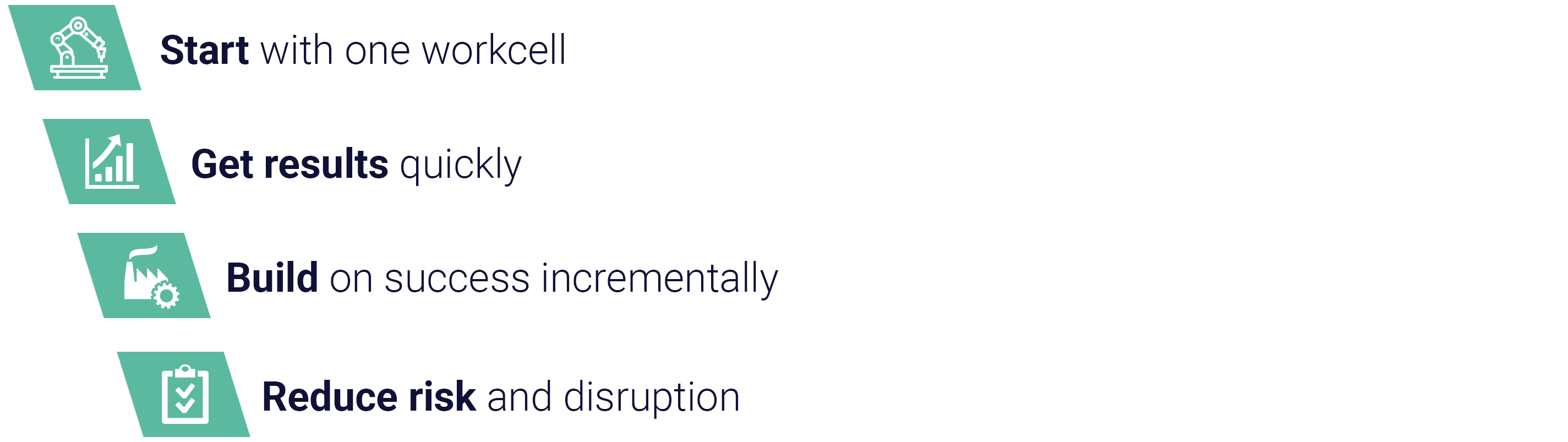

Autonomy enabling

the smart factory

at scale or one

operation at a time

Flexxbotics’s ability to use the robot to coordinate multiple machines and have in-line inspection results automatically correct the machining operations is totally unique and was key for us.”

NEW WHITE PAPER