By Tyler Bouchard 12/05/2024

CNC Automation vs Robotic Machine Tending; Which is Better?

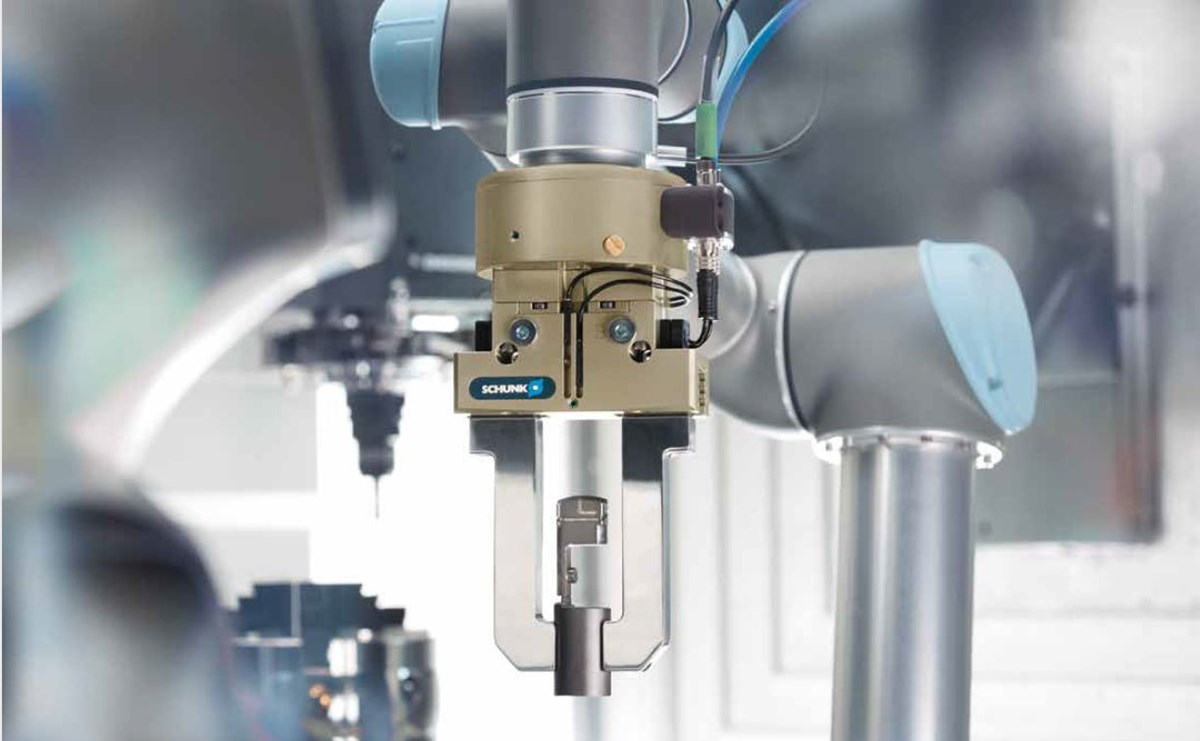

Now it’s important to make the distinction between conventional CNC automation and using robots for machine tending with CNCs.

The term “CNC automation” refers to CNC machines with specific add-on components like part feeders, pallet loaders, and CNCs with robot arms built into the machine itself.

While these systems can be useful in certain cases they lack the flexibility, functionality, and agility that come from separate, independent robotic arms used for CNC machine tending.

CNC automation is purpose-built to solve individual problems and is not adaptable to changes in the factory environment significantly limiting its usefulness.

For example, installing a part feeder helps increase the input of material into the machine, however, it does not improve part out-feed and if the part changes or new parts must be run on the CNC, these systems will in many cases be rendered useless restricting smart factory agility.

On the other hand, connecting a robot to the CNC for machine tending provides much greater flexibility to adapt to new requirements, business changes, and production shifts.

In addition, if needed, independent robotic arms can be redeployed to other parts of the factory across numerous use cases.

Use of robots that connect to the machines also provides the ability to add other machines to the set-up for multi-machine, multi-step processing as opposed to a CNC robot built into the machine which only tends to that one machine.

For example in an Advanced Robotic Machine Tending install, a single independent robot can be set up to tend to two or more turning centers along with deburr equipment and a wash down & blow-off cleaning station as well as a CMM for inspection.

For these reasons robots – both collaborative and industrial – have a measurably better Return on Investment (ROI) than single-purpose CNC automation.

We’ll discuss CNC robot machine tending ROI in more depth later in another post. For now, if you’d like to learn more you can get our Complete Guide to Robotic Machine Tending Projects