By Flexxbotics: 09/11/2024

Flexxbotics Announces Transform Production with Robotic Machine Tending Webcast with Universal Robots

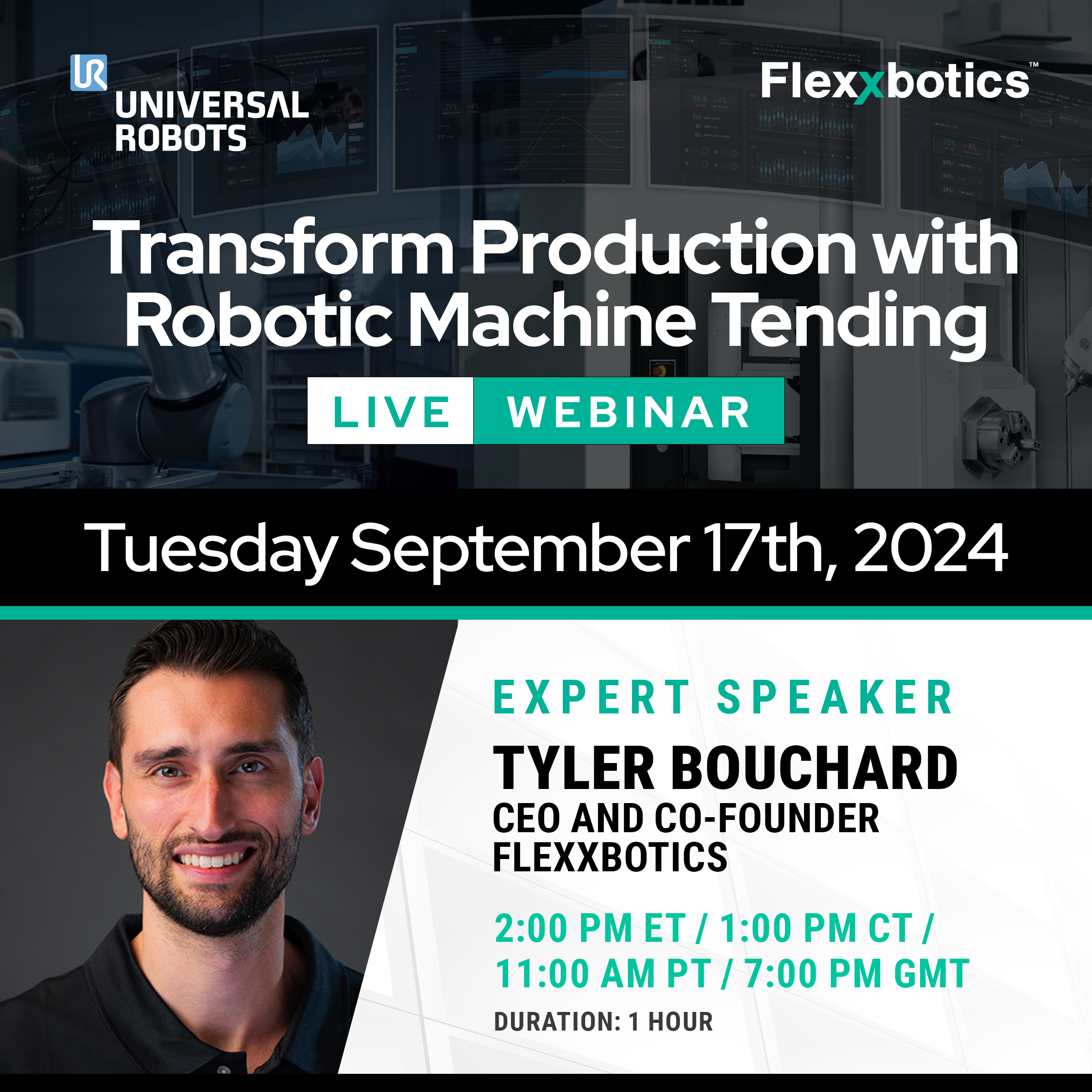

Boston, MA – 11 September, 2024 – Flexxbotics, delivering digital solutions for robot-driven manufacturing at scale, today announced the upcoming online webinar, Transforming Production with Robotic Machine Tending. This event with Universal Robots will be hosted by Machine Design on Tuesday 17 September at 2pm EST. Free to Attend | Register Now.

The promise of collaborative robots in manufacturing is significant, and has proven a highly capital-efficient strategy to increase revenue and expand EBITDA. Achieving greater capacity, productivity and quality using robots results in increases in both throughput and profit per part. Additionally, waste, scrap & rework are minimized, safety is improved, and energy consumption is decreased per unit of output for greater sustainability.

The scope and scale of the benefits attained are directly determined by a plant’s ability to operate robot-enabled production continuously with precision and quality. Utilizing advanced robotic machine tending with in-line inspection for closed-loop processing adjustments in real-time is essential for attaining autonomy in process control and running unattended. Autonomous process control is the critical capability that enables fleets of robots to run ‘lights out’ in the smart factory.

In this session, you will hear from Brian Conner; CSI/CSP Program Manager from Universal Robots and Tyler Bouchard; CEO & Co-Founder from Flexxbotics, as they explain the Smart Factory Production Robotics Maturity Model along with the benefits, challenges and results attainable with a comprehensive production robotics digitalization strategy.

You will learn about the stages of maturity and considerations for your personnel, the robots, existing machines & equipment, solutions and investments to ensure your business objectives are achieved.

“We believe that autonomous process control is a prerequisite for autonomous manufacturing in the smart factory,” said Tyler Bouchard, CEO & Co-founder of Flexxbotics. “We look forward to sharing our real-world experiences with leading companies utilizing production robotics at this upcoming webinar with UR.”

To register for the event, visit: https://flexxboticsinc.com/md-webcast-em

About Universal Robots

Universal Robots is a leading provider of collaborative robots (cobots) used across a wide range of industries and in education. Founded in 2005 with global headquarters in Odense, Denmark, the company has over 20 offices worldwide, including North America headquarters in Novi, MI. Universal Robots aims to create a world where people work with robots, not like robots. Its mission is simple: Automation for anyone. Anywhere.

Since introducing the world’s first commercially viable cobot in 2008, Universal Robots has developed a product portfolio reflecting a range of reaches and payloads and has sold over 75,000 cobots worldwide. An extensive ecosystem has grown around the company’s cobot technology creating innovation, choice for customers and a wide range of components, kits and solutions to suit every application.

For more information, please visit www.universal-robots.com.

About Flexxbotics

Flexxbotics enables robot-driven manufacturing at scale. Flexxbotics solution digitalizes robotic production with autonomous process control for next generation smart factory environments. Flexxbotics breakthrough, the unique FlexxCORE™ technology, seamlessly connects and coordinates robots with existing automation equipment, IT systems and people. More powerful, flexible and open, Flexxbotics revolutionizes the use of robotics in complex production. Visit www.flexxbotics.com to learn more and follow us on LinkedIn.