By Tyler Bouchard 04/28/2025

Why Factory Robotics Must Work for Everyone and How It’s Happening Now

Wanted to thank Aaron Prather for featuring Flexxbotics in his recent article: “Robotics for the Rest of Us: Why Main Street Can’t Wait.” If you haven’t read the article yet, you can check it out here at this link: https://sixdegreesofrobotics.substack.com/p/robotics-for-the-rest-of-us-why-main

Aaron clearly points out that robotic automation must be made practical and accessible for businesses of all sizes. Basically, he’s saying that robots have to work without the custom science projects required today.

Production Robotics Reality

Sadly, most robot projects fail because they rely on custom, one-off software technology – especially in industries like medical devices, aerospace, and defense, where installations often become overly complex science projects.

At Flexxbotics, we’re fully aligned with Aaron’s vision. We believe that for robotic automation to truly scale across your factory, robot cells must be usable, adaptable, and modularized to be deployed and run by your teams.

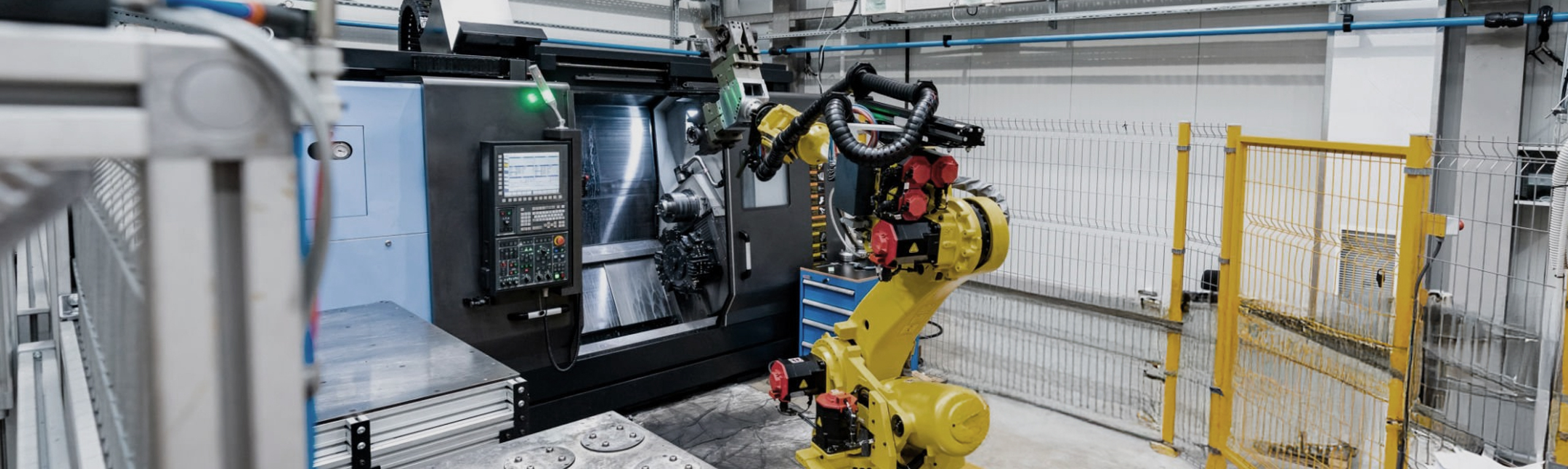

And it’s not just about the robots. To be effective production robotic automation needs to be part of your factory’s operations, not just stand-alone technology in isolation. Robots must communicate with your factory’s machines to coordinate work execution for safe, continuous operation.

To run with any level of unattended autonomy, robots also need to receive instructions from your IT business systems about what jobs to run >> What parts to make, lot quantities, quality specs, other production info… In other words, robots must be part of your manufacturing process to scale out effectively.

Robot’s Way Forward

At Flexxbotics we call this Robot-Driven Manufacturing. It’s why we’ve created standardized robotic production software at the heart of the Flexxbotics solution. Unlike the custom automation integration projects required yesterday, we’ve made our solution powerful, flexible, and open so that it can be deployed quickly, adapted easily, and scaled rapidly in companies of all sizes.

The result? A modular solution for production robots that works for all different types of factories from the largest global organizations to smaller tier suppliers. Able to handle a wide range of parts from complex geometry parts and multi-part assemblies to simple stock parts. Even parts with ISO 2768 and ISO 286 precision tolerances including Class III orthopedics & implants.

Now, you can run multi-op process for multiple parts/SKUs across multiple machines. Robots can take your parts from multi-step machining through post-processing, cleaning, and even inspection.

You’re able to do multi-SKU as well for high volume / high mix environments with support for both line clear and non-line clear set-ups. Bar code scanning automatically calculates part quantities across multiple machines, and work order changeovers detect order completion and update part properties for the next order in-feed.

These kinds of capabilities are foundational for advanced robotic machine tending, robotic quality control, and robotic production lines, and represent the ‘tip of the iceberg’ of what Flexxbotics delivers.

It’s what Robot-Driven Manufacturing looks like in practice: automation that’s resilient, scalable, and straightforward to deploy, no matter your size or sophistication level.

Practical Production Robotics

Aaron calls for a shift in thinking – from complex, robot-only perspectives to more holistic and practical solutions. At Flexxbotics, we’ve embraced that perspective, and are providing a solution that’s as robust and adaptable as the businesses we serve.

Whether you’re optimizing a global factory footprint or single plant, your robotic automation should be a practical part of your overall production strategy in our view.

We all should continue championing the stories of businesses that embrace automation to drive innovation and operational excellence. In fact, if you’re interested in real world examples, you can check out this case study on Ruland Manufacturing achieving lights out manufacturing using Flexxbotics.

The future of smart factory robotics is about solutions that truly work for everyone. It’s happening. And we believe it’s a game-changer.