Do any of these sound familiar?

Lack of job revision control and unaccessible work instructions complicating process / execution leading to higher levels of scrap and quality issues.

Legacy DNC’s leading to inefficient execution and transportation waste making each job less profitable.

Long setup times and costly rework diminish output and increases product lead times decreasing your overall capacity and revenue.

What Is FlexxConnect™?

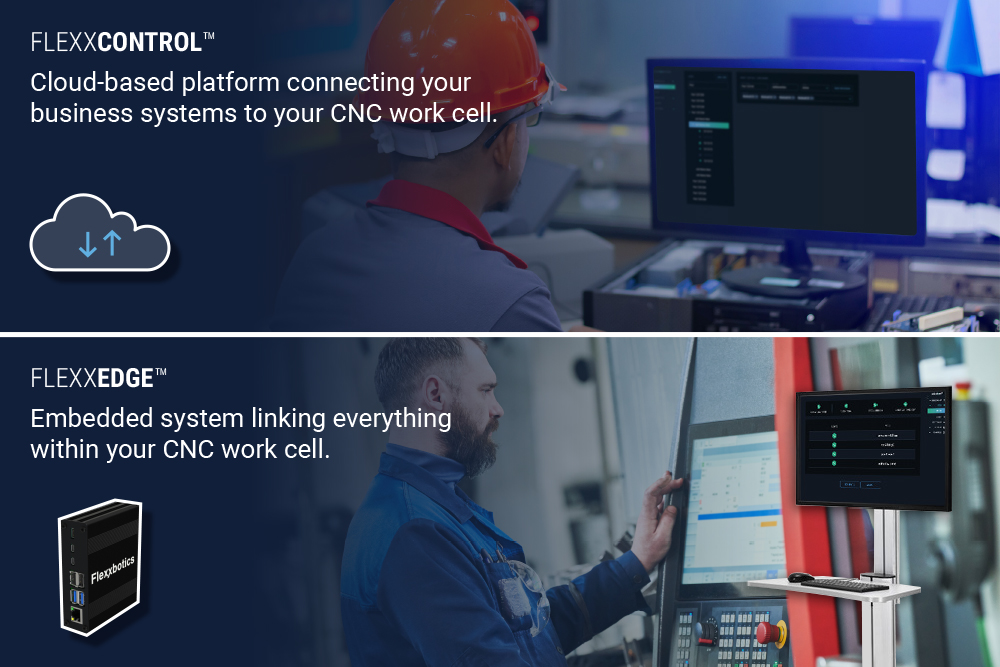

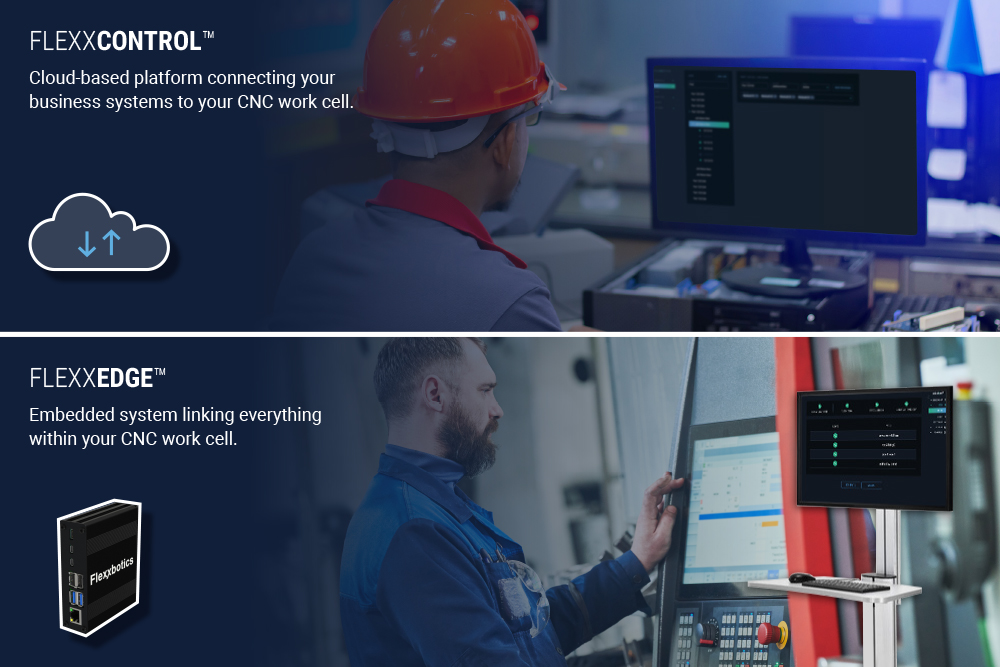

FlexxConnect™ is a digitally centralized system that enables effective process control for your CNC floor by instantly driving the necessary and relevant information to and from your CNCs. It provides your machinists with everything they need to successfully execute your jobs.

- Manage job revision control in one central location

- Upload/download both G-code & robot programs to & from your CNCs

- Send work/tooling instructions, quality alerts, digital media instructions instantly

Configure, Manage & Deploy Jobs

1. Configure your job workflow: Create a step-by-step workflow including modules such as G-code programs, robot programs, work instructions, and digital instruction sets.

2. Manage job revision control: Ensure the correct and latest G-code program or tooling instruction file is being used every time. See history of your jobs and reuse versions of previous jobs to efficiently create new jobs.

3. Deploy your jobs instantly: Send your completed jobs digitally to your CNC work cell to be completed by your machinist or operators.

Workflow

1. Operator Sign In: FlexxEdge™ provides an operator sign in with role-based access control. This provides ability to control tasks between operators as well as an audit trail as to who is performing the work.

2. Execute Your Jobs: Operators have everything they need to run any jobs sent to their work cell from FlexxControl™. G-code programs automatically upload to your machines and easily pull the latest revision back into FlexxControl™ all from your CNC work cell.

3. Customize Your Workflows: FlexxConnect™ allows you to cater your workflows based on what matters to each CNC workcell, your overall operations and the skill level of your operators.

FlexxConnect™ helps you improve CNC work cell

utilization, efficiency and quality, leading to:

Faster Capital Equipment ROI’s

Reduced Scrap / Rework

Higher Output

Higher OTD / Better Customer Satisfaction

Compatible With Robots

Whether you plan to invest in automation or you’ve already invested heavily in automation, FlexxConnect™’s technology works seamlessly with collaborative robots. Learn about our complete automated machine tending solution FlexxTend™!

Combining FlexxConnect™ with Datanomix’s next generation CNC production monitoring provides your machine shop with a continuous improvement platform. Get the enhanced benefit of knowing how your shop is running and having the tools to make it more productive.

Scale as you need!

FlexxConnect™ pricing allows for scaling at your own pace. We understand digital transformation is a difficult process that takes time to implement. We want to help you succeed. Start with a trial unit to get started!

LEARN MORE AND GET STARTED…

"*" indicates required fields

Flexxbotics values your privacy. Website terms and conditions.