Flexxbotics

Autonomous Manufacturing Software

for “Lights Out” Production at Scale

What is Autonomous Manufacturing Software?

Autonomous manufacturing software functionality for advanced machine tending, quality control, and production lines

Power for your Robots

Automated Changeover

Autonomous Process Control

Real-Time Robot Awareness

Easy for your People

HMI Screens & Workflows

Alarms & Escalations

Reports, Dashboards, and Analytics

Safety

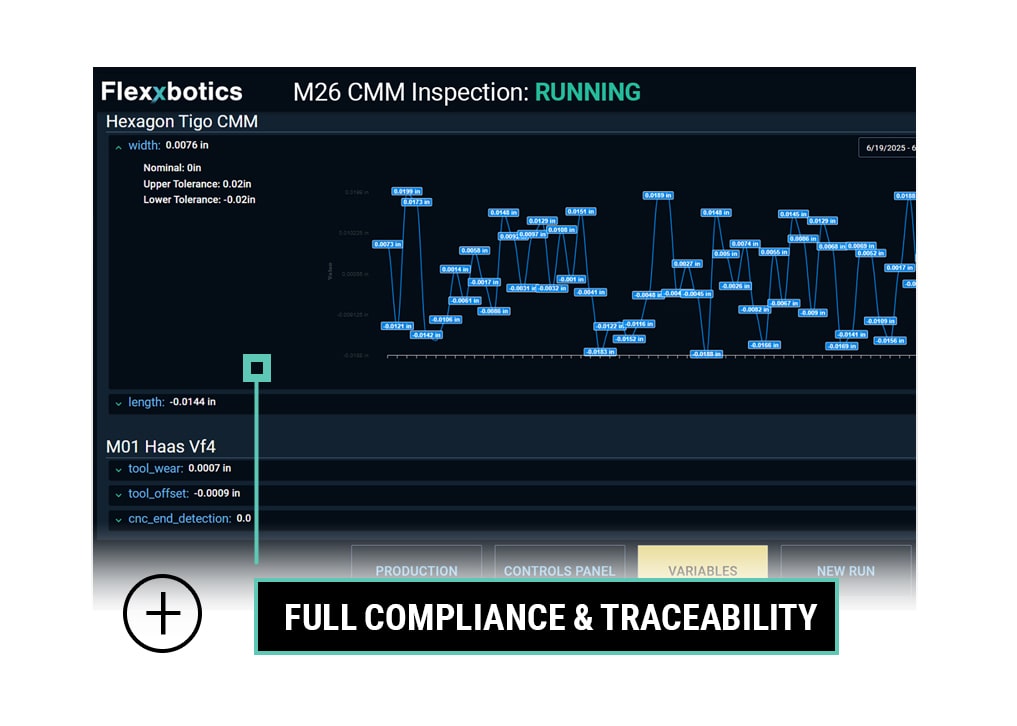

Compliance & Traceability

Program Version Control

Infrastructure & Security

Business Software Connectivity

Administration & Low-code Configuration

Developer Capabilities

Power for your robots

Flexxbotics provide complete functionality for scaling production robotic automation factory-wide and beyond

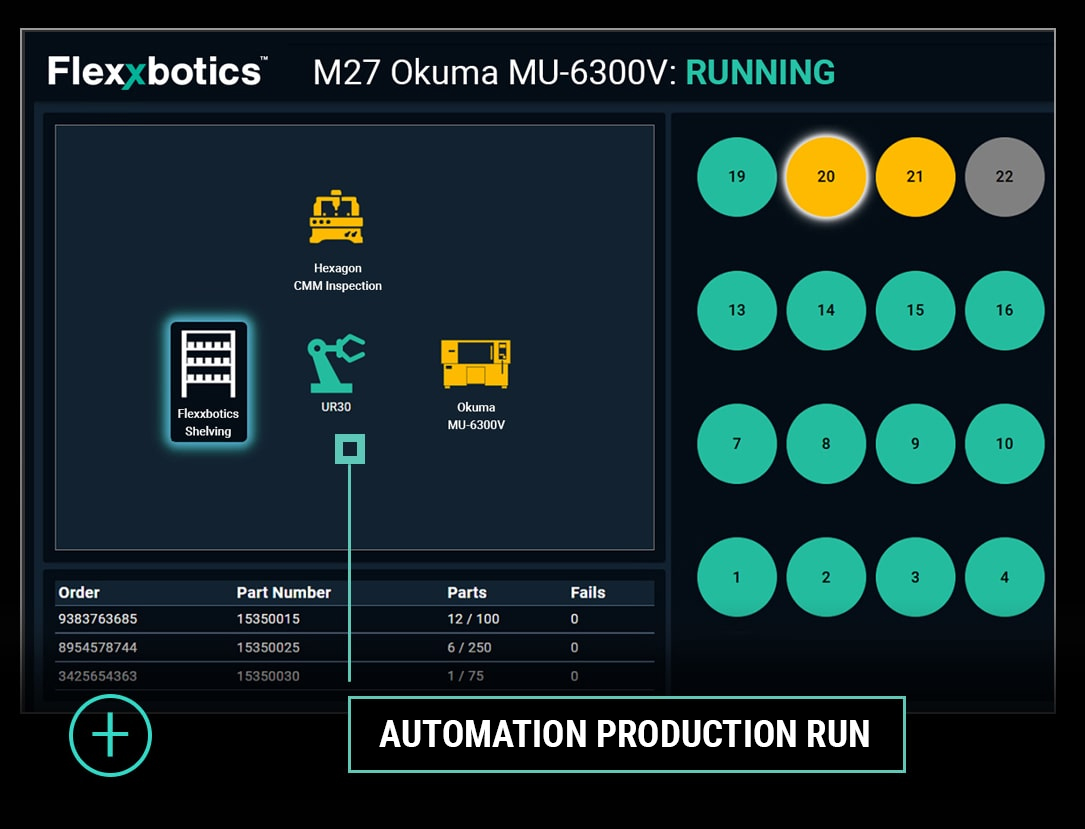

Cell Automation

- Loading and Unloading Parts / Units

- Configurable Rules and Conditionals

- Operational Automation Sequencing

Machine-to-Automation Interfacing

- Start/End Cycle, Digital I/O, and Safety

- Multi-Machine Controller Protocol Interoperability

- Variable/Register/Macro Updates and Parameter Writing

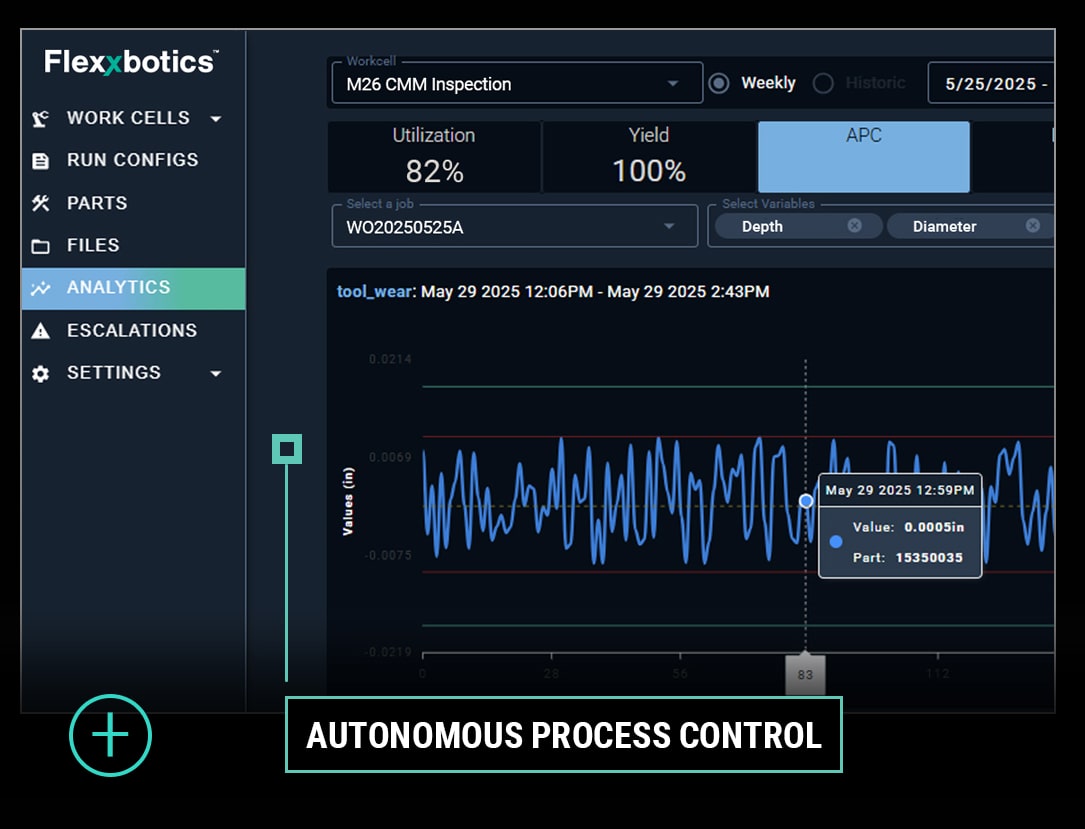

Autonomous Process Control

- Closed-loop Feedback Drives Production Processing Corrections

- Real-time Sensor Readings Direct Parameter/Offset Adjustments

- Configurable Algorithms, Targets & Control Limits, and Actions

Real-time Robot Awareness

- Robots Know Operational State of Machines & Equipment Connected

- Production Progress, Pass/Fails, Downtime, and other events

- Comprehensive Automation Event Logging

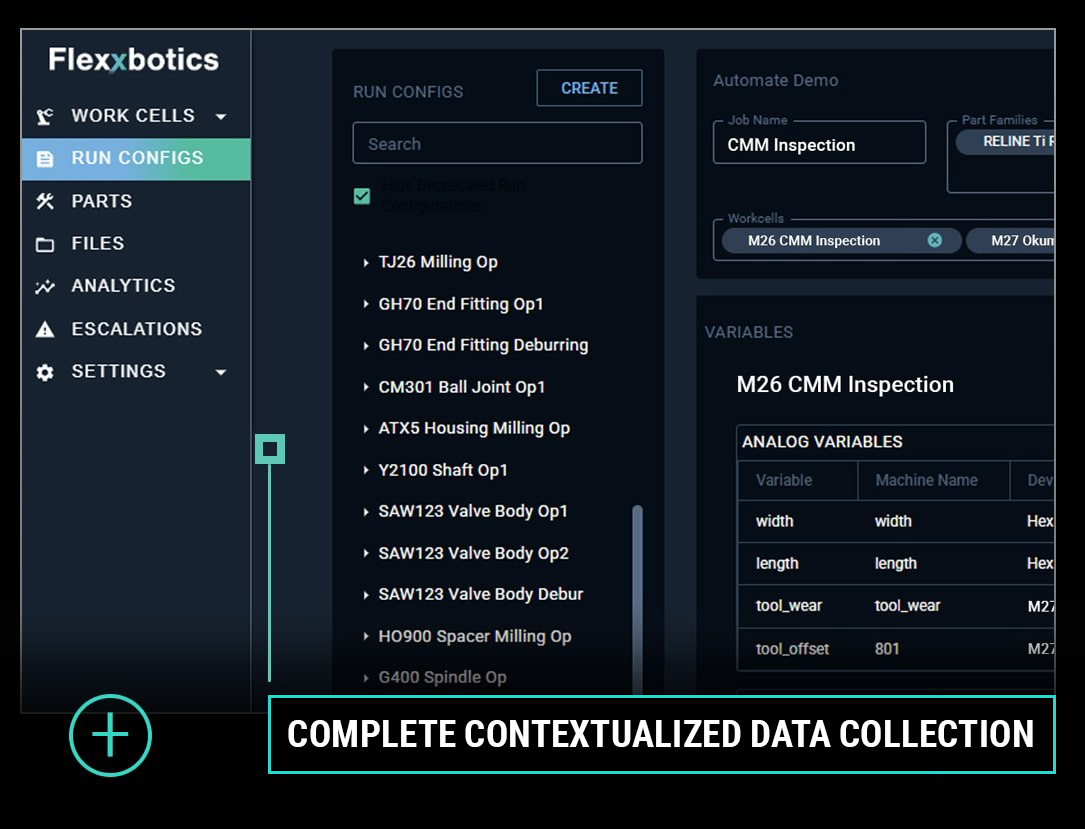

Automation Production Data

- Part Count, Cycle Times, Defects, Status Changes, Work Stops, and other configurable attributes

- Jobs based on Work Orders for Parts / Units / Lots

- Contextualized History of Time Series Event Data and Values

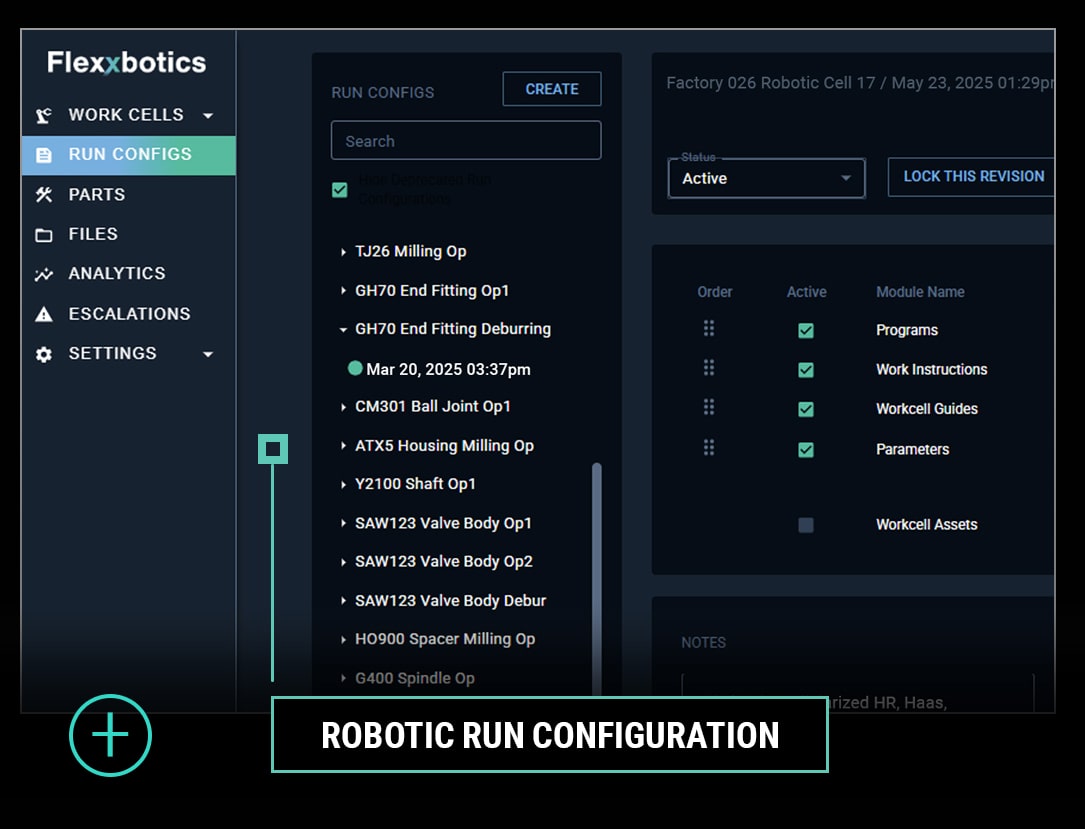

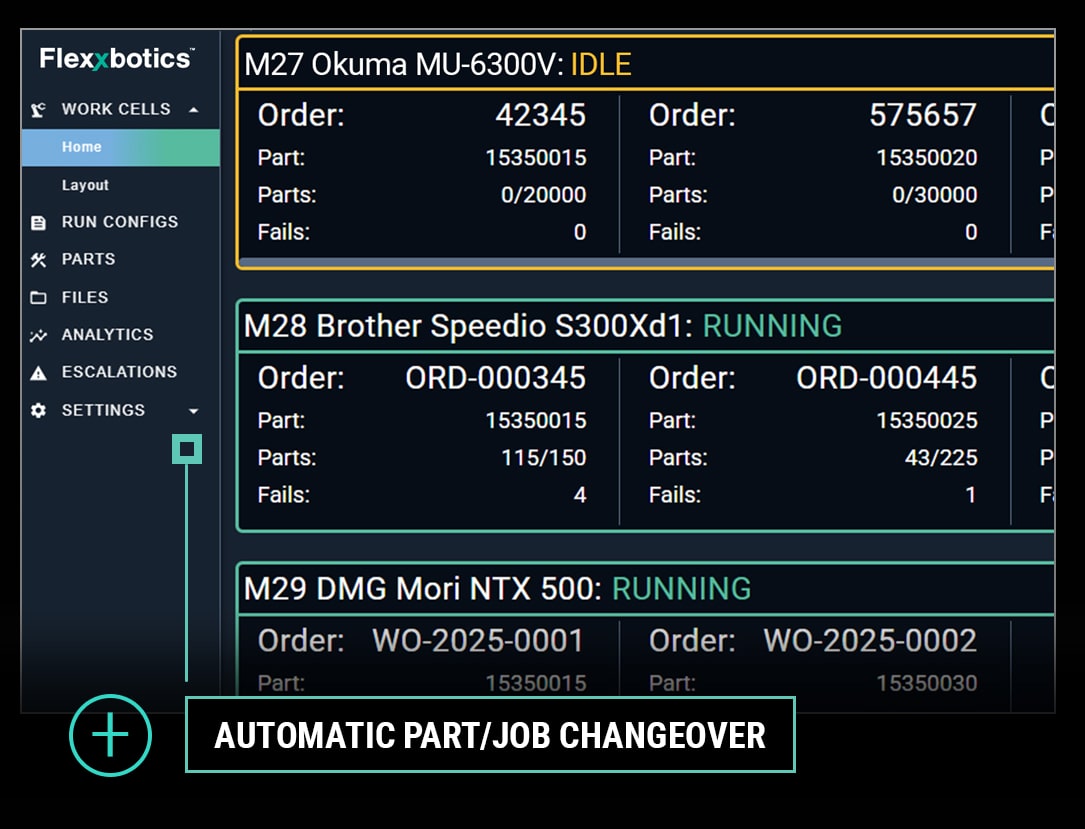

Automated Changeover

- Run Multiple Parts / Units with Auto-Changeover

- Full Traceability, Control, and Segregation

- Automatic Program Loading & Parameter Setting

Easy for your people

Flexxbotics makes powerful robotic automation accessible for all your factory personnel from engineers and operators to technicians and executives

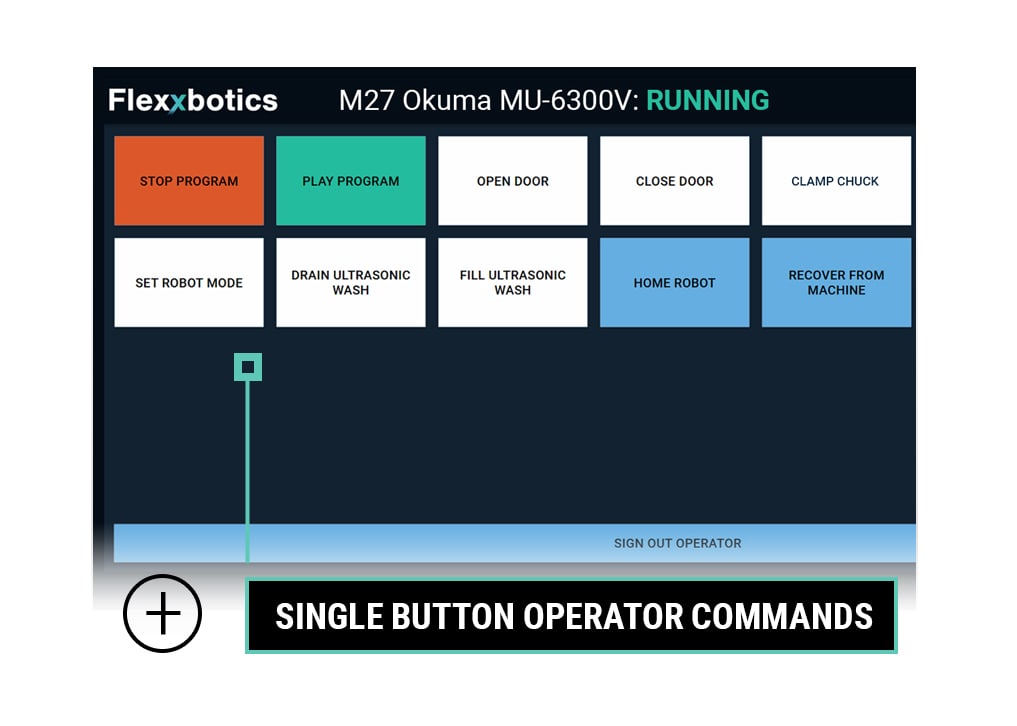

HMI Screens & Workflows

- Powerful Engineering Automation

- Flexible Part Set-up Interface for Adding Parts & Part Families

- Configurable Single Button Operator Screens and Step-by-Step Workflows

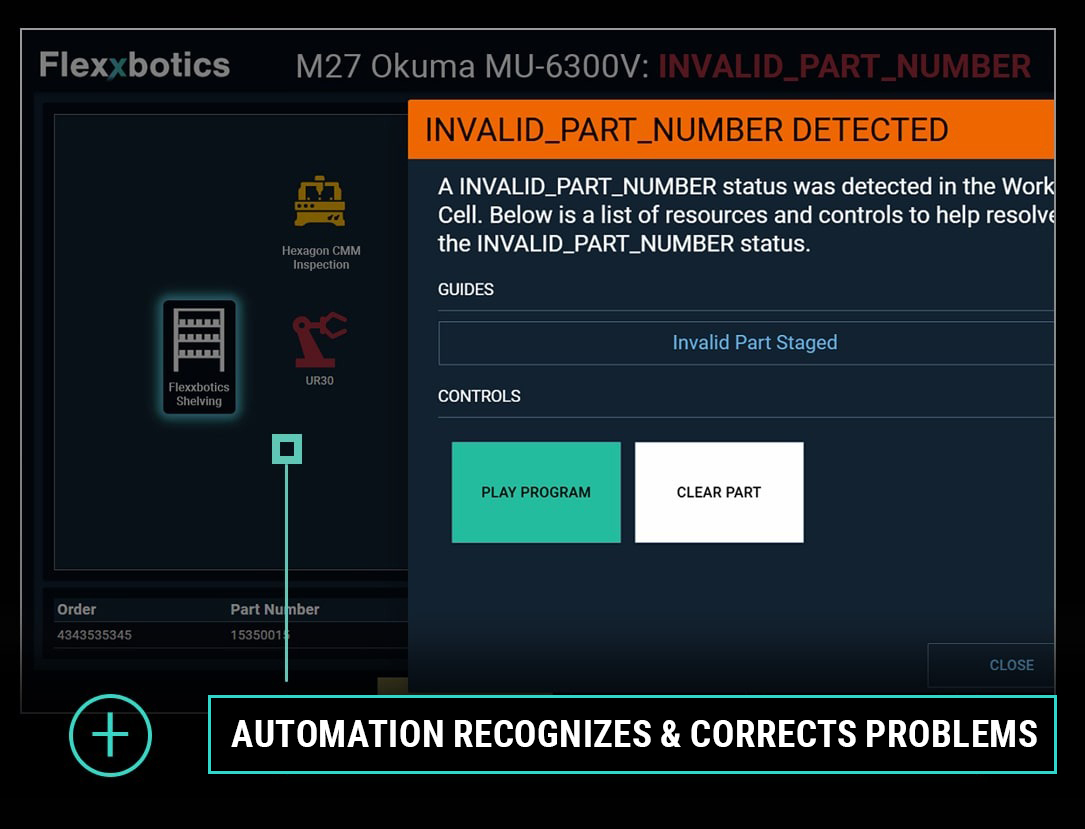

Alarms & Excalations

- Stack Light Signals, Operator HMI Alarms, and Text/Email Escalations

- Clickable Links Straight to Specific Issue

- Event Data Context proceeding Failure, Stop Work, or Downtime

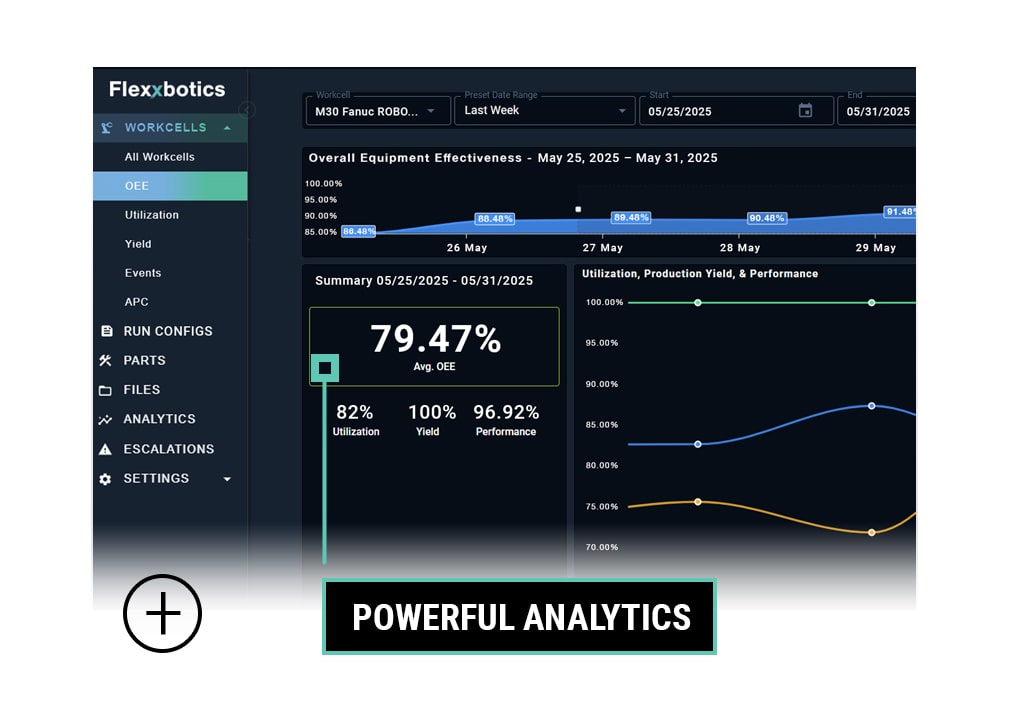

Reports, Dashboards, and Analytics

- Throughput, Utilization, Yield, Unattended Time, OEE, and more

- Dashboards, Pareto Analysis, Trend Analytics, and Scheduled Reports

- Access for 3rd Party BI Tools, Data Lakes, and AI/ML Models

Safety

- Safety Event Alarms and Diagnostics

- Machine/robot status checks verify safe, valid states before and during operation

- Compatible with Safety PLC’s, Emergency Stops, Laser Scanners, Light Curtains, and more

Compliance & Traceability

- Supports ISO-13485, CGMP, AS9100, and other Regulatory Compliance Standards

- Part-by-Part Production Data Capture for Digital Thread Traceability

- Change Control Revision History and Audit Trail Compliance

Automation & Equipment Program Control

- Program Selection & Transfer to Robots, Machines, and Equipment

- Network Drive, Cloud Drive, or DNC Connected Configurations

- Program Version Control & Backup

Infrastructure & Security

- Offline and Online Operation

- Parallelized Data Pipelines and High Performance Persistent Storage

- Encrypted Data in Transit and at Rest

Business Software Connectivity

- API and batch for connecting Automation to existing Factory IT Systems

- Open connectivity for either On-Premise or Cloud applications

- ERP, MES, QMS, LIMS, SCADA, IIoT, and others

Adminstration & Low-Code Configuration

- Unlimited User Defined Properties / Data Element Definition and Extensibility

- UX Screen Layout, Button Configuration, and other functions

- Business Rules, Triggers, and Conditional Logic Modeling

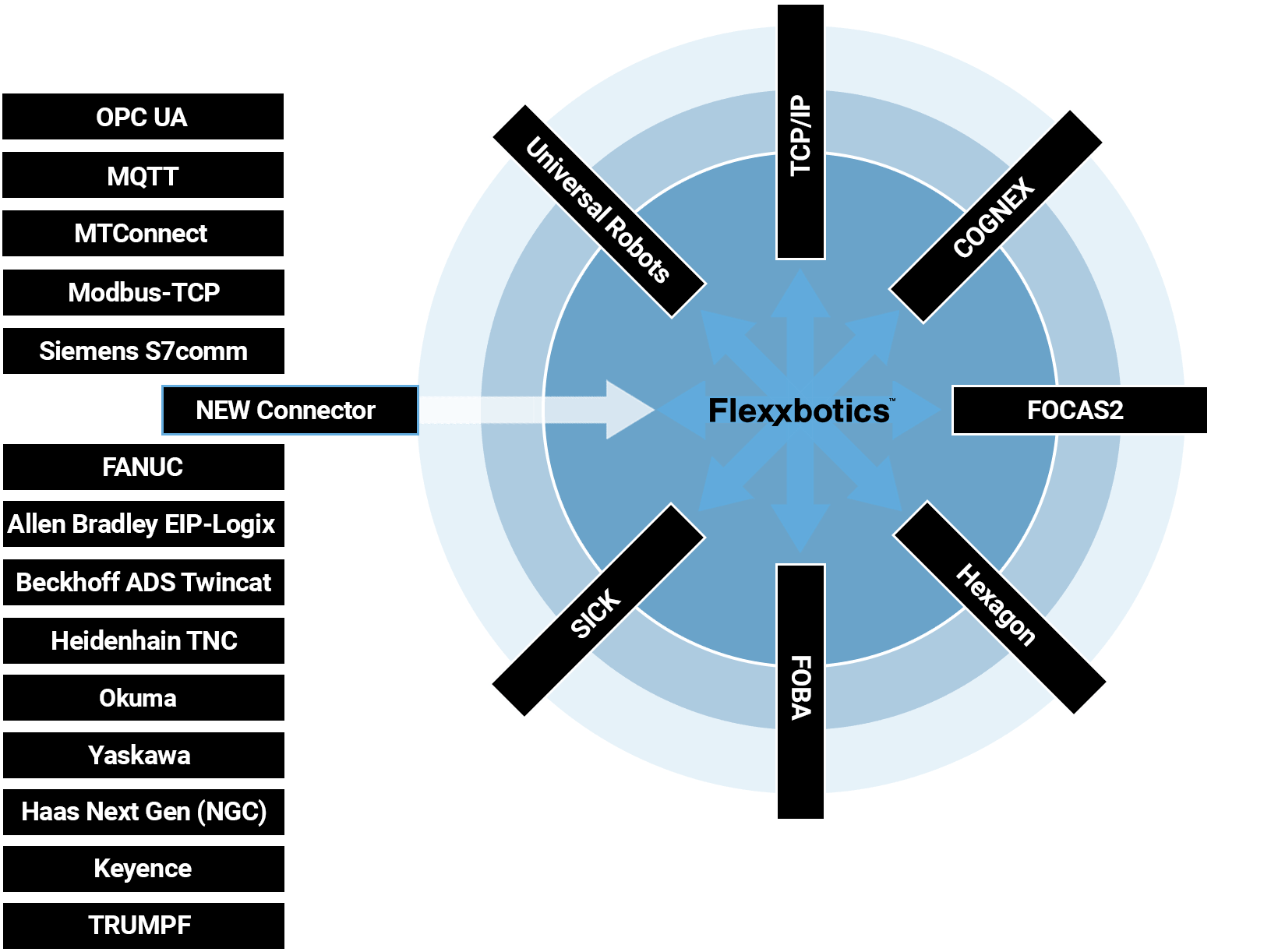

Developer Capabilities

- Develop and Upload Connector Drivers for Controller Interoperability

- Python scripting for Automation Sequencing, Workflows, and Data Manipulation

- Swagger API for Test and Debug

Only Flexxbotics Makes All Your Factory Equipment and Automation Talk

FlexxCORE™ is the unique breakthrough at the center of the Flexxbotics solution which makes robots communicate with over a 1000 makes & models of machines

Transformers

Connector Drivers

Flexxbotics

GitHub Repository

Open-source Transformers compatible with

FlexxCore, the runtime engine at the center of

the Flexxbotics software-defined automation platform

Flexxbotics

GitHub Repository

Open-source Transformers compatible with

FlexxCore, the runtime engine at the center of

the Flexxbotics software-defined automation platform

Open connectivity with your business systems

Fits into your IT environment

to complement & extend the full range of existing systems

Flexxbotics horizontal integration of our robots and machines was impressive, and what made the solution completely unique was the ability to vertically integrate our pre-processing, post-processes, and IT systems.

LEARN MORE | REQUEST A DEMO

"*" indicates required fields