By Tyler Bouchard 03/06/2025

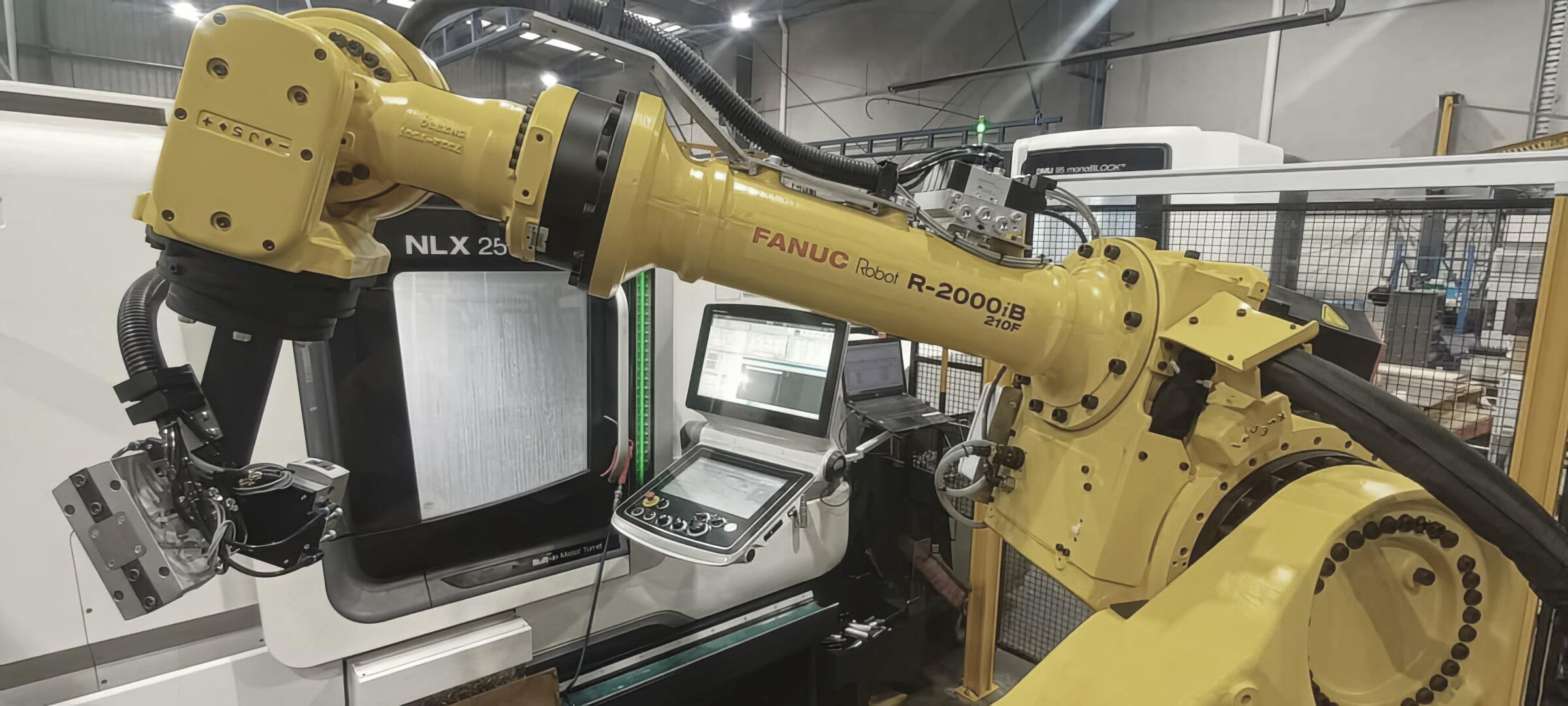

When is CNC Robot Machine Tending Right For Your Factory?

In today’s post, I want to talk about how you can work out if robotic machine tending is right for your factory.

Let’s start with a few questions first:

- Do you need longer unattended runs?

- Are labor uncertainties hindering your output and On Time Delivery?

- Does your factory need to maintain margins in the face of tariffs?

If your answer to any of these questions is ‘yes’, then you probably want to learn more about robotic machine tending.

Robotic machine tending maximizes equipment utilization during existing shifts as well as nights, weekends, and holidays without human oversight, and can be especially beneficial when facing labor or skills challenges.

Additionally, if keeping margins intact is important, robotic automation will be important to your strategy.

You can increase productivity while reducing waste by improving your factory’s machine-to-man ratio in turn lowering labor costs. All in all, your operations will have greater EBITDA profitability.

I’ll go over the basics here today and you can always read more in our Complete Guide to Robotic Machine Tending Projects paper.

You Need Longer Unattended Production

Robotic machine tending enables factories to achieve longer periods of unattended production.

Not only can robots operate 24/7 without the need for breaks, they enable your machines to run continuously all day long including nights, weekends, and holidays.

This capability increases utilization and output to meet production goals without constant human oversight.

You Have Labor & Skills Challenges

Factories that face labor uncertainty or a lack of skilled workers turn to robot machine tending to address workforce challenges.

With new immigration restrictions, an aging workforce and fewer qualified workers available to operate machines, robots are the most cost effective way to keep production running while reducing dependence on hard-to-find talent and historical know-how.

Robots also enable experienced operators to focus on more value-added work while the factory maintains consistent output.

You Must Drive Profit Margins

Automating CNC machine tending with robots can help maintain margins in the face of materials price increases and tariff expenses to maintain and even improve EBITDA profitability.

Robots increase production rates and reduce rework and scrap while simultaneously lowering labor costs by improving the machine-to-person ratio.

Using robots for machine tending helps optimize Overall Equipment Effectiveness (OEE) as well, leading to lower operational costs and higher profit margins per part produced.

For more insights into robotic machine tending, you may want to explore our CNC Robot Machine Tending Essentials blog, or if you’d like to discuss specifics on an upcoming project get in touch with us directly.