CNC Robot Machine Tending Essentials

How to automate your CNCs with robots

Executive Summary

When undertaking a robotic machine tending initiative there are numerous factory-dependent and project-specific considerations that must be taken into account.

Identifying which requirements are relevant to an initiative and to what extent is critically important to achieving project goals.

These can range from the business objectives driving the project’s Return On Investment (ROI) and budget to desired outcomes, facility constraints, operational and equipment trade-offs, technical requirements, and many more.

This post summarizes the different aspects of a robot machine tending initiative that deserve attention to achieve overall success.

Download Complete Guide

to Robotic Machine Tending

White Paper

What Is Robotic Machine Tending?

Basic robotic machine tending automates simple steps such as loading raw materials into CNCs and unloading finished parts. Production robotic automation can be applied to CNCs and other factory machines using different types of robots – typically either industrial robots or power & force-limiting robots known as collaborative robots – which improve machine uptime operation, productivity, and output.

What Is Advanced Robotic Machine Tending?

CNC Automation vs Robotic Machine Tending

It’s important to make the distinction between conventional CNC automation and using robots for machine tending with CNCs. The term “CNC automation” refers to CNC machines with certain add-on components like pallet loaders, part feeders, and CNCs with robot arms built into the machine itself. While these systems can be useful in certain cases they lack the flexibility and functionality that come from separate, independent robotic arms used for machine tending.

CNC automation is purpose-built to solve individual problems and is not adaptable to changes in the factory environment. For example, installing a part feeder helps increase the input of material into the machine, however, it does not improve part out-feed and if the part changes or new parts need to be run on the machine, then these systems will in many cases be rendered useless which limits factory agility.

On the other hand, connecting a robot to the CNC for machine tending provides much greater flexibility to adapt to new requirements, business changes, and production shifts. If needed independent robotic arms can be redeployed to other parts of the factory across numerous use cases.

Use of robots that connect to the machines also provides the ability to add other machines to the set-up for multi-step processing as opposed to a CNC robot built into the machine which only tends to that one machine. For example a single, independent robot with a pair of turning centers and a CMM for inspection along with deburr, wash down, and blow-off.

For these reasons robots – both collaborative and industrial – have a better return on investment (ROI) than single-purpose CNC automation.

Why Use Robots For CNC Machine Tending?

Robots enhance CNC machine tending by automating repetitive tasks like loading, unloading, material handling, inspection, and other operations. This improves efficiency, reduces human error, and enables machines to run continuously, leading to increased productivity and consistency in operations. Robots also operate in conditions that are unsafe or injury prone which reduces liability risk. Robotic systems can also handle different parts and processes, making them ideal for dynamic manufacturing environments. Such benefits include:

Operation

Improved

Yields

Greater

Capacity

per Part

Increase Unattended Operation:

Robots enable unattended operation by enabling CNC machines to run without human intervention for extended periods, such as overnight graveyard shifts or during weekends and holidays. This leads to more consistent output, reduced downtime, and overall higher equipment utilization, maximizing production efficiency while freeing human operators for more complex tasks.

Improved Yields:

Robots operate with precision and repeatability which helps improve yields by minimizing errors and defects. The consistency of robotic systems reduces nonconformances, scrap and rework, and ensures that parts meet specification. Advanced setups can include autonomous process control with defect avoidance for six sigma levels of quality and better yields.

Greater Capacity:

Robotic machine tending increases a facility’s throughput capacity by enabling machines to operate continuously without the necessity for breaks. With robots handling routine tasks, more parts can be processed within the same timeframe, enabling factories to handle larger production volumes and respond more quickly to demand swings.

Higher Profit per Part:

Robotic automation used for CNC machine tending results in higher profit per part by reducing defects, downtime, and labor costs. The improved quality, increased efficiency, and lower operational costs translate into higher profitability for each part produced, giving manufacturers better margins overall.

What Types of Processes and Machines are Right for Robotic Machine Tending?

Robotic machine tending is highly adaptable across a range of processes and machines, making it ideal for most manufacturing environments, especially advanced manufacturing factories.

Commonly automated processes include turning and machining, inspection & test, injection molding (such as insert molding and overmolding), additive manufacturing, assembly, kitting, and disassembly. Robots are also effective for production lines that require repetitive, precise handling of parts. Quality inspection and testing, in particular, benefit from robotic consistency, as automated inspection technologies operate with less variation than manual operations, improving the reliability of inspection results.

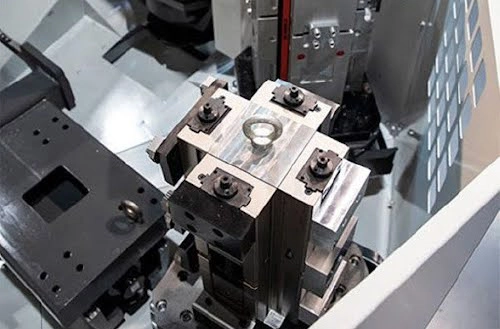

The types of machines suitable for robotic tending are equally varied, covering a diverse array of mills, lathes, Swiss lathes, vertical and horizontal turning centers, and complex machining like five-axis and specialty machines. Advanced equipment such as multi-tasking machines, B-axis swing turrets, and multi- or single-turret setups can also be robot-enabled.

Additionally, robotic tending can integrate with laser markers & engravers, EDMs (electrical discharge machines), brake presses, honing machines, CNC grinders, and more, extending automation capabilities throughout the facility.

Inspection equipment can be seamlessly incorporated into robotic workflows for enhanced accuracy and productivity including vision systems, laser systems, probes, telecentric measurement systems, coordinate measuring machines (CMMs), and electronic test equipment and PCB testing.

Robots are also well-suited to operate secondary machinery like deburring tools, washdown and blow-off units adding further flexibility to automate comprehensive, end-to-end processes.

What Kinds of Parts are Best for Robotic Machine Tending?

Robotic machine tending is versatile enough to handle a wide array of part types, from complex geometry components and multi-part assemblies to simple stock parts. Advances in robotic end-of-arm-tooling have made it possible to manage parts with intricate shapes, tight tolerances, and uniform, repetitive requirements where precision and consistency are critical.

Robots can handle a diverse range of form factors, surfaces, and materials, making them ideal for processing parts with consistent shapes, weights, and surface textures. Robotic systems can accommodate materials from metals and alloys to composites, plastics, and delicate surfaces without causing damage or contamination. Even parts that adhere to ISO 2768 and ISO 286 precision tolerances are suitable for robotic machine tending, including Class III orthopedic and implantable components, which must conform to strict standards in manufacturing. Parts best suited for robotic machine tending are typically those with consistent handling needs.

Today, the use of robotic machine tending is applicable across a broad spectrum of industries, enhancing efficiency and quality in both high-volume and high-mix production environments. The continuously expanding breadth of part types is invaluable in sectors like medical devices, semiconductor, automotive, aerospace, space, and defense manufacturing, where parts often have complex geometries and require specific handling to meet regulatory compliance requirements.

Can Part/Job Changeover be Automated?

Just like CNC machines have programs, robots require programmatic instructions for each part and job type. So for a basic CNC-to-robot configuration each part involves a program for the CNC and a program for the robot. In more sophisticated setups involving multiple machines and inspection equipment each part will have a program for each machine included along with the robot. Each changeover requires synchronized program loading so the robot and all associated machines get the correct program for the part that will be processed.

A helpful way to approach this is to recognize that nearly every mechanical change—whether switching parts, adjusting workholding, updating CNC tooling, or changing robot grippers—typically requires a corresponding software adjustment. When managing these changes across multiple machines, software adjustments can quickly add up, creating a significant burden to manage without mistakes unless robotic production software is in place.

A powerful robotic production software solution like Flexxbotics automates the changeover process by providing features like automatic program loading, parameter setting, and real-time parametric adjustments. This transforms the hundreds or even thousands of software adjustments required in a factory with multiple robots into a quick and efficient automated process. Additionally, operators can schedule multiple, sequential changeovers – with line clear for compliance if required – as long as the necessary mechanical aspects are in place as well.

Flexxbotics reduces changeover complexity by completely automating all aspects associated with robot and machine programs during changeover, as well as, providing the option to use barcode scans for job changeover with automated program loading and adjustment setting to assure coordination when enabled.

Other changeover considerations that should be taken into account during the design of the robotic machine tending installation include:

- Is the part presentation area sufficient for the full range of parts?

- Does the workholding in the machines cover all the different part geometries?

- Will the robot’s end-of-arm tooling be sufficient to pick up and hold all the different parts?

When running a variety of parts in a robotic machine tending setup, using adaptive technologies can significantly enhance flexibility and efficiency. Force-feedback grippers allow for precise handling of parts with different geometries, weights, and materials while automatic end-of-arm tooling (EOAT) changers and multipurpose EOATs enable quick transitions between tasks without manual intervention. Dual EOAT grippers further increase throughput by handling multiple parts simultaneously, and palletized workholding helps streamline part positioning for consistent, repeatable operations.

An automated changeover process can significantly reduce downtime and make it feasible for robots to handle changeovers on numerous part types without manual intervention. Without a solution such as Flexxbotics that includes an automated changeover process, these tasks can introduce unnecessary downtime and slow production, reducing the efficiency gains of robotic automation.

What are Common Challenges in CNC Robot Machine Tending?

While robotic automation offers many benefits, using robots for CNC machine tending presents certain challenges that are not always obvious. These include interfacing between the robots and the CNC machines, managing multi-machine operations, and part presentation for robots as opposed to humans to enable autonomous “lights-out” production. Addressing these challenges is essential for achieving efficient and reliable operation of production robots.

Part Presentation In-Feed / Out-Feed

An often overlooked consideration in CNC robot machine tending is that robots require consistent part presentation. Robots need parts consistently positioned for in-feed and out-feed operations. If parts are randomly aligned or jumbled, the robot may pick and load them incorrectly. This makes it important to organize part staging for robotic requirements.

Robot-to-Machine Interface

Another challenge in CNC robotic machine tending is overcoming connection and communication incompatibilities between robots and CNC machines. Machine PLCs and protocols are not inherently compatible. The lack of standards often presents unanticipated issues and can be endlessly frustrating. Custom integrations offer limited functionality, are overly complex to install and difficult to maintain over time. Standard off-the-shelf interfacing solutions for interoperability such as Flexxbotics represent the best option in many cases.

Multiple Machine Robot Operation

When deploying robots across multiple CNC machines, referred to as advanced robotic machine tending, process workflow considerations become critically important. Any combination of multi-machine, multi-part, multi-step operational requirements means the robots have to operate in a coordinated manner in the overall process. Managing the timing and coordination of tasks is crucial to avoid unexpected stoppages and bottlenecks to ensure consistent operation. The robot must be able to transition between different machines and tasks without mistakes or unplanned downtime. In addition, different machines often have different controllers with different protocols as noted previously which can complicate set-up and ongoing operation further. Standardized interfacing solutions like Flexxbotics become essential in these configurations.

Achieving “Lights Out” Automation

“Lights out” operation where production runs continuously without human intervention requires more than just robots. Production process orchestration becomes essential including not just loading and unloading, but tool wear detection, defect identification, sorting, corrective action, and more. All must be fully automated and synchronized. This requires sophisticated interoperable coordination between the robots, CNC machines, and other factory equipment, as well as, robotic production software that manages the parts, jobs, changeovers, workflows, and processes for unattended operation. Standard digital solutions such as Flexxbotics are intended for these types of complex smart factory robotic operation at scale.

When is CNC Robot Machine Tending Right For Your Factory?

CNC robot machine tending is right for your factory when you need to extend unattended production, improve throughput, and increase margins. Robotic machine tending maximizes equipment utilization during nights, weekends, and holidays without human oversight, and can be especially beneficial when facing labor shortages or skills challenges. Additionally, if profit margin increases are important, robotic automation increases productivity, reduces waste, and improves the machine-to-person ratio lowering labor costs leading to more efficient operations and higher EBITDA profitability.

You Need Longer Unattended Production

CNC robot machine tending enables factories to achieve longer periods of unattended production. Robots can operate 24/7 without the need for breaks, enabling machines to run continuously all day long and during nights, weekends, and holidays. This capability increases utilization and output to meet production goals without constant human oversight.

You Have Labor Shortage & Skills Challenges

Factories that face labor shortages or a lack of skilled workers turn to CNC robot machine tending to address workforce challenges. With an aging workforce and fewer qualified workers available to operate machines, robots offer a cost effective solution reducing dependence on historical know-how and hard-to-find talent. Robots also free up existing workers to focus on more value-added activities while the factory maintains consistent production output.

You Must Increase Profit Margins

Automating CNC machine tending with robots also improves EBITDA profitability. Robots increase production rates and reduce rework and scrap while simultaneously lowering labor costs by improving the machine-to-person ratio. Using robots for machine tending helps optimize Overall Equipment Effectiveness (OEE) as well, leading to lower operational costs and higher profit margins per part produced.

What are the Smart Factory Production Robotic Maturity Model Stages?

The Smart Factory Production Robotics Maturity Model provides a roadmap for evolving from manual, human-operated production to fully autonomous, robot-driven manufacturing. As companies progress through the model, they achieve increased productivity, yields, safety, and margins by integrating and advancing robotic machine tending capabilities within production workflows.

The model emphasizes a shift from basic machine tending to advanced robotic machine tending with highly coordinated, autonomous robot fleets, enabling seamless, “lights-out” operations.

The maturity model, developed by Flexxbotics, highlights the operational and strategic benefits of robotic adoption, helping companies achieve scalable, synchronized, and optimized smart factory robotic environments.

Stage 1: Conventional Factory Machining – Automated machines are operated manually by humans; limited process automation and significant reliance on skilled labor.

Stage 2: Traditional (Basic) Robot Machine Tending – Robots load and unload machines, primarily for efficiency and safety; connectivity is limited causing interfacing challenges.

Stage 3: Robotic Process Enablement– Robots are integrated into workflows, coordinating operations and synchronizing production; improved machine-to-person ratios.

Stage 4: Autonomous Process Control – Robots manage workstations independently using inspection results to adjust processing instructions; enables precise quality and minimizes human intervention.

Stage 5: Robot-Driven Manufacturing – Fleets of robots across smart factories operate with interconnected orchestration managed by robotic production software; seamless coordination and “lights out” operation.

The Smart Factory Production Robotics Maturity Modeldemonstrates the transformative potential of robots in achieving fully autonomous plant environments. By using this model, manufacturers can strategically advance their operations to increase efficiency, reduce costs, and improve EBITDA margins.

What are the Robotic Machine Tending Project Phases?

Implementing a robotic machine tending solution requires a structured, phased approach to ensure success from design through daily operation. Each phase — Design & Deploy, Validate & Optimize, and Operate & Maintain — is essential to ensure a robust, efficient, and reliable solution.

Starting with thorough planning and deployment, followed by rigorous testing and optimization, and into ongoing operation and maintenance, these phases guide teams to achieve an effective automated solution. This phased approach enables manufacturers to increase project implementation success, ensure safety, and achieve sustained operational excellence.

Design & Deploy

In the Design & Deploy phase, the project’s foundations are laid out, starting with a comprehensive assessment of project requirements, choosing the right equipment, and designing the layout for efficient and safe operation. This phase involves setting up the entire robotic system along with all machine programming and establishing robot-to–machine(s) communication and process coordination. Effective installation design planning and project implementation ensure that the system is positioned for success in subsequent stages.

Validate & Optimize

The Validate & Optimize phase focuses on testing, verifying, and fine-tuning the robotic machine tending setup. Here, the system undergoes thorough validation to verify performance, accuracy, and safety standards. Adjustments are made to reduce inefficiencies, optimize cycle times, and increase throughput. This phase is essential to ensure that the system ramps smoothly and meets the intended performance and safety specifications before full-scale production operations.

Operate & Maintain

In the Operate & Maintain phase, the robotic machine tending system enters regular production operations. Continuous monitoring ensures consistent performance, and preventive maintenance routines are established to avoid unplanned downtime. The intent is optimal system operation over a multi-decade lifespan. This ongoing phase emphasizes reliability and support for long-term operational efficiency.

Robotic Machine Tending – 15 Point Project Planning Outline

Developing a structured plan and roadmap to guide factory robotic machine tending automation initiatives is critically important and should include these 15 areas:

- Business Goals & Target Outcomes

- Selecting Operations to Automate

- Requirements & Constraints

- Budgeting & Return On Investment (ROI)

- Internal Communications Plan

- Identifying Parts & Part Families

- Throughput Volume & Cycletimes

- Objective-based Design

- Robot+Machine Connectivity

- Business Systems Connectivity

- Safety & Risk Assessments

- Validation Testing

- Documentation & Training

- Ramping Volumes

- Maintenance & Support

Flexxbotics offers full turnkey services and support for robotic machine tending installations from design and deployment through validation, optimization, operation and ongoing maintenance.

Next Steps: CNC Robot Machine Tending – Project Checklist

In modern manufacturing environments, CNC machine tending with robotics has become essential for improving throughput, efficiency, precision, and safety. This checklist outlines the key components necessary for successful CNC robot machine tending setup projects.

From the primary CNC machines and automated inspection with robots or cobots to supporting or secondary automated systems such as deburring, laser marking, and other pre/post processing steps each operation plays a critical role in streamlining production.

The checklist outline will help in assessing and establishing a thorough CNC robot machine tending system including in-feed/out-feed mechanisms, end-of-arm tooling, and safety features, as well as other important considerations.

Deeper Details: Connecting Robots to Your CNC Machine

Connecting a robot with a CNC machine unlocks the potential for “lights out” production, maximizing machine utilization and achieving high operational efficiency. However, seamless robot-to-CNC communication remains a challenging yet crucial component for achieving this level of automation. A robust communication setup between the robot and CNC is essential to enable the robot to perform repetitive, high-precision tasks without human intervention.

CNC Auxillary Functions

Experienced CNC technicians understand the standard operating parameters of CNC machines, yet additional points are necessary when connecting a robot to the CNC. Each function, from part loading to end-cycle detection, must be carefully mapped to ensure smooth robot+CNC automation.

G-Code

G-Code serves as the primary programming language for CNC operations, dictating specific machining instructions. This code type, combined with M-Codes and Macros, enables a flexible and responsive program for complex tasks. Modifying core G-Code can be complicated and time-intensive for engineers; thus, solutions that maintain existing G-Code integrity while layering in automation functions offer significant time savings and operational efficiency. Flexxbotics, for instance, leverages Macros and M-Codes to enable sophisticated robot+machine automation without altering essential G-Code cutting instructions.

M-Codes

M-Codes handle auxiliary machine operations, such as initiating the spindle or starting the machine. Automating these M-code-controlled functions is essential for efficient CNC robot machine tending, covering tasks such as operating vises and chucks, opening and closing doors, and initiating start/stop cycles. For example, activating coolant with M08 or calling subroutines with M98 allows for versatile programming within automated workflows. While some CNC machines have these controls pre-integrated, retrofits often require third-party systems. For example, a lathe might come with automated chuck and door controls, whereas an older milling machine may need additional add-ons for similar functionality. Flexxbotics standardized solution utilizes M-Codes to operate auxiliary operations improving unattended operations and safety.

Macros

Macros streamline the programming process by allowing reuse of common functions within the main code. Acting as modifiable variables within the CNC program, macros save programming time and support flexible, dynamic automation. For robot installations, macros can facilitate frequent robotic functions, such as flipping parts or debris blow-off, enhancing efficiency. Flexxbotics uses Macros to enable advanced automation, including seamless interaction between multiple machines or use of real-time data from automated inspection equipment like a CMM to adjust CNC parameters dynamically.

By addressing these communication and functionality layers, Flexxbotics creates a standardized and agile robotic automation solution where industrial robots and cobots work with CNC machines seamlessly for high-precision, efficient production.

Advanced Topics: Achieving “Lights Out” Manufacturing

Advanced topics in robotic machine tending, such as Autonomous Process Control (APC) and IT business systems connectivity, are essential for achieving “lights out” manufacturing. APC enables robots to autonomously adjust processing based on real-time inspection data, correcting issues like tolerance drift to maintain precision, reduce defects, and improve yields. Additionally, seamless integration with enterprise systems (ERP, MES, QMS, and others) is needed, as outlined by ANSI/ISA-95. Standardized digital solutions offer secure APIs for open connectivity to enable comprehensive data flow and digital process coordination without complex custom setups, supporting efficient and sustainable smart factory production for continuous operations.

Autonomous Process Control

Autonomous Process Control (APC) in robotic machine tending uses robots, machine-based automated inspections, and smart factory digitalization robotic production software. Without consistent APC autonomous production is not feasible. Process control autonomy is the critical condition that must be achieved to attain “lights out” autonomous manufacturing.

APC enables robots to autonomously adjust CNC production processing based on results from automated inspection technologies and other real-time data sources such as sensors. This type of closed-loop system enables proactive processing corrections, assuring consistently high-quality production output without human intervention.

For example, as CNC tool wear occurs tolerance drift can result in nonconformances being made. Flexxbotics Autonomous Process Control capabilities identify tolerance drift and make proactive offset corrections to maintain production to specification and avoid defects.

By automating production processing adjustments based on real-time inspection results, APC improves precision, reduces waste, and improves yields, particularly in industries with stringent regulatory compliance.

IT Business Systems Connectivity

ANSI/ISA-95 is the Enterprise-Control System Integration standard that defines a framework for seamless data and information exchange between enterprise and control systems in manufacturing.

Per ANSI/ISA-95 robotic machine tending projects should take into account how to connect with existing factory IT systems for digital process integration, data integrity, and production analysis.

Each company has its own systems of record in place – ERP/MRP, MES, QMS, PLM/PDM, DNC, CAD/CAM, SCADA/HMI, IIoT, Business Intelligence, custom systems and others – and interfacing to one or more of these systems will be important at some point.

For example, ensuring production data records are updated and/or quality inspection results are stored is important for factory performance tracking and digital thread traceability. In addition, secure data access is critical for analytics and reporting.

Standard Application Programming Interfaces (APIs) are an important consideration up-front to avoid costly and complex custom coding and integration. Solutions like Flexxbotics are designed with secure APIs for open connectivity to existing business systems providing bi-directional data flow. Flexxbotics enables factories to leverage current infrastructure, enhancing automated workflows, and overall process coordination without needing a complete overhaul, thus supporting a more connected and agile production environment.

Compliance Requirements: Safety & Risk Assessments

Safety and risk assessments are essential when implementing CNC robotic machine tending installations to protect both factory personnel and equipment as well as avoid potential liability.

These assessments evaluate potential hazards associated with robotic operations, such as moving parts, high-speed equipment, and unexpected stops or starts. In CNC robotic machine tending, risks can stem from the robot’s movements, the CNC machine’s operation, or both, which may pose risks of entrapment, collision, pinch points, or other dangerous situations. Safety measures are crucial to mitigate these hazards and ensure safe operation and can include emergency stops, interlocked barriers, light curtains, and safety-rated robots and machine controllers.

A thorough risk assessment identifies specific dangers in the installation layout, robot reach, and interaction points between the robot and CNC machine. It also evaluates the potential for human interaction, especially in collaborative robot (cobot) setups. Cobots often work near humans, so they are designed with safety features such as force and speed limitations, however the work environment must still be carefully reviewed. When risks are identified, controls like reduced robot speed, protective guarding, or programming adjustments can be implemented.

Regular training for operators on safety procedures, combined with scheduled maintenance checks, are also vital. By conducting a comprehensive risk assessment, manufacturers can create a safer CNC robotic machine tending environment that complies with industry safety standards, minimizes downtime due to safety incidents, and fosters a culture of safety within the facility.

Flexxbotics provides comprehensive safety mitigation as part of installation designs and offers both safety and risk assessments as an optional service for installations of the Flexxbotics solution.

Flexxbotics uses and recommends the following regulations and standards to minimize risks and ensure safe working environments for employees interacting with robots and machinery in CNC robotic machine tending: ANSI B11.0 and ANSI/RIA R15.06 along with EN ISO 12100, 10218-1, 10218-2, ISO/TS 15066, and OSHA Regulations CFR 1910 Subpart O for Machine Guarding.

Investment Planning: Budgeting & ROI Justification

Budgeting and ROI justification are essential steps in planning a robotic machine tending project, as they ensure the investment aligns with financial and operational goals. Initial costs typically include the robot, tooling, software, integration expenses, and possible retrofits for compatibility of existing equipment. Operational expenses, like maintenance and training, should also be factored into the budget.

To justify Return On Investment (ROI), manufacturers should consider long-term benefits, such as increased capacity, yield improvements, reduced labor costs, and minimized downtime, which contribute to the payback periods. Metrics like profit per part, cycle time improvements, defect reductions, and machine-to-man ratio increases are critical in assessing ROI, along with non-monetary advantages like improved safety, agility, and compliance.

Effective budgeting and ROI analysis can demonstrate how robotic machine tending increases quality, enhances efficiency and lowers costs over time, supporting the business case for robotic automation.

RFP Starter Template Example for CNC Robot Machine Tending

The Request for Proposal (RFP) starter template example is for CNC robot machine tending project and includes basic sections and language to help manufacturers clearly outline project requirements and evaluate vendor responses.

Best Practices: Steps to Success in CNC Robot Machine Tending

Following best practices is essential for success in robotic machine tending initiatives from beginning with clear business goals and thorough planning to ensuring that the operating and support plan align with strategic priorities and operational efficiency.

Defined Business Goals: Establish clear business objectives and target outcomes to ensure financial viability and alignment with strategic priorities.

Thorough Planning: Develop a detailed project plan that outlines objectives, timelines, and requirements for successful robotic machine tending implementation.

Involve Stakeholders: Engage the appropriate factory personnel and managers early including mechanical, automation, and production engineers, as well as plant and production managers, to ensure alignment, authorization, and ongoing support.

Target Consistency: Focus on automating machine tending operations that are uniform and predictable to simplify project designs and setups and achieve quick wins.

Mitigate Risks: Conduct thorough risk assessments and implement appropriate safety measures to protect both workers and equipment.

Standardize Solutions: Choose modern standardized digital solutions that connect and communicate to a wide range of machinery and systems for supportability, extensibility and future scalability across factory operations.

Ongoing Support: Ensure an ongoing support plan for long-term operating reliability, maintenance, and rapid issue resolution.

Common Pitfalls: Obstacles to Success for CNC Robot Machine Tending

Avoiding common pitfalls is crucial to the success of robotic machine tending projects, as issues like undefined goals, inadequate preparation, and lack of communication can quickly derail progress and reduce project effectiveness.

Undefined Business Goals: Neglecting to identify specific business objectives and target outcomes results in unrealistic expectations and often perceived project failure.

Inadequate Preparation: Insufficient planning and design considerations for robotic enablement leads to deployment issues and suboptimal performance.

Lack of Communication: Failing to keep relevant factory stakeholders informed and up-to-date leads to lack of buy-in, commitment, and support and can result in misalignment and substantial resistance.

Selecting Complexity: Attempting to automate inconsistent or overly complex operations complicates implementation unnecessarily and measurably reduces project success rates.

Skipping Safety: Overlooking safety assessments and mitigation measures exposes workers to risk and can lead to injury incidents, compliance issues, and corporate liability.

Creating Custom Systems: One-off system software is unsustainable over time, difficult to support, and cannot be readily extended to additional machines, robots, or equipment limiting factory agility.

Using Legacy IT Systems: Force-fitting various outdated IT systems requires extensive customization and complicates integration resulting in ineffective robotic machine tending operation if possible at all.

Do-It-Yourself vs Integrator Consultants vs Solution Providers

When considering robotic machine tending projects, manufacturers have three primary options:

- Do-It-Yourself (DIY)

- Integrator Consultants

- Solution Providers

DIY offers the lowest upfront cost although requires significant in-house expertise and resources often leading to extended project timelines, ongoing operational challenges, and longer time-to-resolve issues that arise. In addition, typically only one or two people will know / understand the ins & outs of the setup which over time presents supportability risk.

Integrator Consultants or Systems Integrators bring specialized knowledge and project-specific customized systems, although they can have higher costs and introduce programming complexity creating ongoing dependency for support.

Solution Providers offer off-the-shelf, standardized solutions that are not custom coded for each project and are therefore less complex to deploy and extend to other machines in the factory. Standard solutions provide reduced implementation risk and shorter lead times with better, more responsive support. In addition, standardized solutions like Flexxbotics provide powerful out-of-the-box functionality for automation, analytics, and alerts, as well as superior capabilities for security and business system connectivity.

Why Choose a Standard Solution for Robotic Machine Tending?

The reasons to choose a standard solution such as Flexxbotics for robotic machine tending are numerous. From functionality, flexibility, and deployment speed to safety, reliability, and ongoing supportability, utilizing Flexxbotics standardized solution exceeds custom installations on all dimensions.

Flexxbotics solution offers a powerful and scalable approach to production robotic automation. As opposed to one-off installations based on complex PLC programming where each deployment is a custom stand-alone system, Flexxbotics provides a standardized robotic production software package that is designed for operational reliability and supportability in advanced manufacturing environments with stringent compliance requirements.

Flexxbotics solution includes robot+multi-machine interoperable communication and orchestration for open connectivity with over 1000 makes and models of factory machinery and a wide range of IT systems.

Standard solutions such as Flexxbotics reduce deployment time, lower the risk of implementation errors, and include dedicated support, making it easier to achieve quick ROI while maintaining flexible automation that can extend to different machines and workflows as production needs evolve.

About Flexxbotics

Flexxbotics enables robot-driven manufacturing at scale. Flexxbotics solution digitalizes robotic production with autonomous process control for next generation smart factory environments. Flexxbotics breakthrough, the unique FlexxCORE™ technology, seamlessly connects and coordinates robots with existing automation equipment, IT systems and people. More powerful, flexible and open, Flexxbotics revolutionizes the use of robotics in complex production.

Visit www.flexxbotics.com to learn more and follow us on LinkedIn.