CAREFULLY READ THIS SOFTWARE END USER LICENSE AGREEMENT (“AGREEMENT”) WHICH GOVERNS YOUR ACCESS TO ALL OF THE FLEXXBOTICS SOFTWARE YOU ARE ABOUT TO ACCESS, DOWNLOAD AND/OR INSTALL (THE “LICENSED SOFTWARE”). THIS AGREEMENT IS MADE BETWEEN FLEXXBOTICS INCORPORATED (“FLEXXBOTICS”) AND THE INDIVIDUAL PERSON ACCESSING, DOWNLOADING, INSTALLING, OR USING THE LICENSED SOFTWARE ON YOUR OWN BEHALF OR FOR YOUR EMPLOYER (HEREINAFTER, “LICENSEE”). THE LICENSED SOFTWARE AND THE RELATED DOCUMENTATION MADE AVAILABLE TO LICENSEE (THE “DOCUMENTATION”) IS MADE SUBJECT TO THE TERMS OF THIS AGREEMENT. FOR CLARITY, ‘DOCUMENTATION’ IS LICENSED FOR USE WITH THE LICENSED SOFTWARE AND IS NOT PART OF THE EXECUTABLE CODE.

BY CLICKING THE ACCEPT BUTTON OR OTHERWISE ACCESSING, DOWNLOADING, INSTALLING OR USING THE LICENSED SOFTWARE, YOU AGREE TO BE BOUND BY AND BECOME A PARTY TO THIS AGREEMENT, AND YOU REPRESENT THAT (i) YOU HAVE READ, UNDERSTAND, AND AGREE TO BE BOUND BY THE TERMS OF THIS AGREEMENT; (ii) YOU ARE OF LEGAL AGE TO FORM A BINDING CONTRACT WITH FLEXXBOTICS; AND (iii) YOU HAVE THE AUTHORITY TO ENTER INTO THIS AGREEMENT. IF YOU DO NOT AGREE TO ALL OF THE TERMS OF THIS AGREEMENT, YOU MAY NOT ACCESS, DOWNLOAD, INSTALL, OR USE THE LICENSED SOFTWARE. IF YOU DO NOT HAVE AUTHORITY TO ACCEPT ALL OF THE TERMS OF THIS AGREEMENT, DO NOT INSTALL, ACCESS, OR USE THE LICENSED SOFTWARE.

A. LICENSE GRANT AND USAGE.

A.1 GRANT OF LICENSE.

A.1.1 License Grant. Subject to Licensee’s ongoing compliance with the terms and conditions of this Agreement, Flexxbotics grants Licensee, upon access or delivery of license keys and during the Term, a limited, non-exclusive, non-transferable, and non-sublicensable revocable license to access, download, install, and use the Licensed Software solely for Licensee’s internal business purposes, as follows:

install one copy of the Licensed Software on computer servers owned or leased by Licensee and permit the use thereof solely by employees, contractors and consultants of Licensee and its subsidiaries and affiliates, and employees of Licensee’s suppliers and customers, and limited to the number of devices and users permitted under this Software License Agreement;

make one copy of the Licensed Software solely for backup and disaster recovery purposes, provided Licensee shall reproduce all confidentiality and proprietary rights notices on all copies of the Licensed Software; and

make a reasonable number of copies of the Documentation and distribute such copies for use in connection with the Licensed Software, provided Licensee shall reproduce all confidentiality and proprietary rights notices on all copies of the Documentation.

A.1.2 Authorized Devices. Licensee may enable and use the Licensed Software on no more than two (2) Authorized Devices in physical world operations, unless otherwise expressly agreed by Flexxbotics in a separate and mutually executed written agreement and corresponding Order Form or Purchase Order specifying the permitted number of Authorized Devices. Each Authorized Device must correspond to a single, unique physical device and may not be shared, time-sliced, virtualized, or otherwise used to enable access by multiple devices or systems. Licensee shall supervise and control the use of the Licensed Software to ensure that it is used only on Authorized Devices in accordance with this Agreement. Any use of the Licensed Software beyond the permitted number of Authorized Devices constitutes an unauthorized use and a material breach of this Agreement.

A.1.3 Authorized Users. Authorized Users may include, for example employees, consultants, contractors and agents of Licensee and its Affiliates. Notwithstanding the foregoing, Authorized Users may not include a direct competitor to Flexxbotics or its Affiliates without the prior written consent of Flexxbotics. You may only allow access to the Licensed Software for Authorized Users unless expressly and otherwise agreed by Flexxbotics in a separate and mutually executed written agreement. Each Authorized User must correspond to one (1) individual user and cannot be shared or used by more than one individual user. Only Authorized Users may access and use the Licensed Software. Licensee shall supervise and control the use of the Licensed Software and ensure that the Licensed Software is used by Authorized Users in accordance with the terms of this Agreement unless otherwise agreed in writing.

A.1.4 System Requirements. Licensee is solely responsible for ensuring that its systems meet the hardware, software and any other applicable system requirements for the Licensed Software as specified in the Documentation. Flexxbotics has no obligation or responsibility under this Agreement for issues caused by Licensee’s use of any third-party hardware or software.

A.2 LIMITATIONS ON USE.

A.2.1 Restrictions on Use. Licensee may only use the Licensed Software as expressly permitted under this Agreement unless expressly and otherwise agreed by Flexxbotics in a separate and mutually executed written agreement. Without Flexxbotics express prior written consent, Licensee may not (directly or indirectly through any employee, contractor, consultant, agent or other representative) (i) sell, lease, sublicense or otherwise permit any use or access any of the Licensed Software, or any derivative thereof to or by any third party, or otherwise use the Licensed Software on a service bureau basis; (ii) reverse engineer, decompile, disassemble, modify or otherwise attempt to derive source code, algorithms, tags, specifications, architectures, structures or other elements of the Licensed Software (except to the extent such prohibition is expressly prohibited by applicable law and then only upon advance notice to Flexxbotics); (iii) create any derivative works of the Licensed Software or Documentation, (iv) interfere with any license key mechanism in the Licensed Software or otherwise circumvent mechanisms in the Licensed Software intended to limit your use; (v) remove any product identification, proprietary, confidentiality, copyright or other notices placed upon or displayed in connection with the Licensed Software; (vi) use the Licensed Software for any unlawful purpose or in violation of any third-party rights; or (vii) disclose, transfer or otherwise make available the results of any performance, capacity or functionality tests or any benchmarking testing of the Licensed Software to any third party. Licensee represents that it is not using the license granted herein as a consumer but will be using the Licensed Software in its business (which may include use within a university or academic setting).

A.2.2 Third Party Software. Portions of the Licensed Software are licensed by Flexxbotics from third party licensors (the “Third Party Software”). For the avoidance of doubt, the use by the Licensee of the Third Party Software is subject to the terms and conditions of this Agreement, including, without limitation, Sections A.2 and A.3. Licensee promises that it (i) will use the Third Party Software only as an integral component of the Licensed Software and (ii) will not modify, adapt, translate, or create any derivative works of the Third Party Software or merge the Third Party Software into any other software.

A.2.3 Updates. Licensee understands that Flexxbotics has no obligation to provide any updates to the Licensed Software or to notify Licensee when an update is available; however, Flexxbotics may require Licensee to install updates as a condition of continued use, provided such updates are intended to maintain functionality, security, or legal compliance. For clarity, this does not obligate Flexxbotics to provide support or maintenance. Please check the location on a regular basis where you downloaded the Licensed Software in order to determine whether an update to the Licensed Software has been made available by Flexxbotics and is required to be installed by Licensee. Any future release, update, or other addition to functionality of the Licensed Software that is made available to Licensee shall be subject to the terms of this Agreement, unless Flexxbotics expressly states otherwise subject to the terms of this Agreement, except as otherwise required by the applicable open-source license.

A.2.4 Software Maintenance. Unless expressly and otherwise agreed by Flexxbotics in a separate and mutually executed written agreement, the Licensed Software is provided without software maintenance or support of any kind.

A.2.5 Usage Data. Flexxbotics owns the usage data derived from the operation of the Licensed Software (“Usage Data”). Nothing herein shall be construed as prohibiting Flexxbotics from utilizing the Usage Data, provided that any such Usage Data shall be aggregated and de-identified so that it will not disclose your identity to any third-party. Flexxbotics may also for business purposes, issue mutually agreed upon press releases, and distribute information, including Licensee’s name and logo and any endorsement by Licensee regarding its use of the Licensed Software.

A.2.6 Open Source. Certain components of the Flexxbotics Materials may be offered under open-source licenses. To the extent required by such licenses, the applicable license terms will govern Licensee’s use of those components, and the corresponding notices and source code (where required) will be made accessible. No open-source license grants Licensee any rights to the Flexxbotics Materials beyond those expressly stated here.

A.3 FLEXXBOTICS INTELLECTUAL PROPERTY.

The Licensed Software is protected by patent, copyright, trademark, trade secret and other laws, including without limitation, international treaties. Except for the limited license rights expressly granted above, all right, title and interest to the Licensed Software, Documentation, the Third Party Software, and any portion or copies of the Licensed Software and Third Party Software, or any other Flexxbotics materials or information provided or made available in connection with the Licensed Software remains exclusively with Flexxbotics or its licensors. This Agreement does not convey any rights of ownership in or to the Licensed Software or Third Party Software and/or any copies, modifications, enhancements, updates, translations, and other derivative works thereof. Licensee may not grant any security interest in the Licensed Software or Licensee’s rights with respect thereto. Third Party licensors, in addition to any other rights or remedies available to them, are third-party beneficiaries of this Agreement with regard to their respective component(s).

A.4 PRIVACY TERMS.

Flexxbotics may collect certain data and information from Licensee and its Authorized Users in connection with its use of the Licensed Software. All such data and information will be collected and used by Flexxbotics in accordance with Flexxbotics Privacy Policy (located at https://flexxbotics.com/privacy-policy/), Licensee hereby agrees that Licensee’s business contact information (including the contact information of its Authorized Users) provided by Licensee to Flexxbotics in connection with the license of the Licensed Software shall be deemed to have been provided with all necessary consents permitting Flexxbotics to process such information for purposes related to this Agreement. It is Licensee’s obligation to obtain any necessary consent required of its Authorized Users to the extent such information has been provided by Licensee to Flexxbotics. Licensee acknowledges that Flexxbotics is part of a global company with global operations, and that personal data may be processed outside of Licensee’s country. All such transfers of personal data shall be in accordance with applicable data privacy laws and as described in the Flexxbotics Privacy Policy.

B. LICENSE TERM.

B.1 Term. This Agreement commences on the date when Licensee accepts (as described above) this Agreement and remains in full force and effect while Licensee has access and use of the Licensed Software, unless terminated earlier in accordance with this Agreement.

B.2 Termination by Licensee. If Licensee wants to terminate this Agreement, Licensee may do so by discontinuing all use of the Licensed Software (including use by its Authorized Devices and Authorized Users) and deleting the Licensed Software from Licensee’s systems.

B.3 Termination of License by Flexxbotics. Flexxbotics has the right to suspend or terminate Licensee’s use of or access to the Licensed Software provided to Licensee for cause, including if Licensee has breached any provision of this Agreement or if Flexxbotics is required to do so by applicable law. Licensee agrees that all terminations shall be made in Flexxbotics’ sole discretion and that Flexxbotics shall have no liability to Licensee or any third party for any termination of Licensee’s account or license.

B.4 Effect of Termination. Upon termination of this Agreement, Licensee’s right to use the Licensed Software will terminate automatically and Licensee must, at its expense, remove and delete all copies of the Licensed Software. Licensee understands that any termination of this Agreement may involve the extraction or deletion of Licensee’s content and/or data associated therewith, if any. Flexxbotics will have no liability whatsoever to Licensee for any suspension or termination, including for deletion of Licensee’s content and/or data. All provisions of this Agreement which by their nature should survive, shall survive termination of this license, including without limitation, ownership provisions, confidentiality, warranty disclaimers, and limitation of liability.

C. GENERAL TERMS AND CONDITIONS.

C.1 DISCLAIMER OF WARRANTIES.

LICENSEE EXPRESSLY UNDERSTANDS AND AGREES THAT TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THE LICENSED SOFTWARE IS PROVIDED “AS IS” AND “AS AVAILABLE”, WITH ALL FAULTS. LICENSEE EXPRESSLY UNDERSTANDS AND AGREES THAT TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, FLEXXBOTICS MAKES NO WARRANTY, REPRESENTATION, OR CONDITION OF ANY KIND, WHETHER EXPRESS, IMPLIED, OR STATUTORY, REGARDING THE LICENSED SOFTWARE AND FLEXXBOTICS DISCLAIMS ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE, AND NON-INFRINGEMENT. LICENSEE AGREES THAT ALL USE OF THE LICENSED SOFTWARE IS SOLELY AT LICENSEE’S OWN RISK. FLEXXBOTICS DOES NOT WARRANT THAT (i) THE LICENSED SOFTWARE WILL MEET LICENSEE’S REQUIREMENTS; (ii) THE LICENSED SOFTWARE WILL BE UNINTERRUPTED, TIMELY, SECURE OR ERROR-FREE; (iii) THE RESULTS THAT MAY BE OBTAINED FROM USE OF THE LICENSED SOFTWARE WILL BE ACCURATE OR RELIABLE; OR (iv) ANY ERRORS IN THE LICENSED SOFTWARE WILL BE CORRECTED. NO OBLIGATION OR LIABILITY SHALL ARISE OUT OF THE RENDERING OF TECHNICAL OR OTHER ADVICE OR SERVICE GIVEN BY Flexxbotics OR ANY THIRD PARTY, INCLUDING WITHOUT LIMITATION ANY FLEXXBOTICS PARTNER. LICENSEE IS SOLELY RESPONSIBLE FOR ANY RESULTS OBTAINED FROM USING THE LICENSED SOFTWARE. NEITHER FLEXXBOTICS NOR ANY FLEXXBOTICS AUTHORIZED PARTNER WARRANTS THAT THE OPERATION OR OTHER USE OF THE LICENSED SOFTWARE WILL BE UNINTERRUPTED OR ERROR FREE OR WILL NOT CAUSE DAMAGE OR DISRUPTION TO LICENSEE’S DATA, COMPUTERS OR NETWORKS.

C.2 INFRINGEMENT CLAIMS.

Flexxbotics does not provide indemnification from any claim or action, including intellectual property infringement claims or actions. If Licensee has accessed, downloaded, installed, or used Licensed Software and any portion of the Licensed Software is held by a court of competent jurisdiction to infringe, misappropriate, or violate any third party intellectual property rights, then the license granted under this Agreement shall immediately terminate and Licensee must immediately stop using the Licensed Software. Flexxbotics has no obligation to indemnify, defend or hold harmless Licensee with respect to the Licensed Software.

C.3 LIMITATION OF LIABILITY.

IN NO EVENT SHALL FLEXXBOTICS NOR ITS DIRECTORS, EMPLOYEES, AGENTS, PARTNERS, OR SUPPLIERS HAVE ANY LIABILITY TO LICENSEE FOR (i) ANY ERROR OR INTERRUPTION OF USE, LOSS OR INACCURACY OR CORRUPTION OF DATA AND/OR CONTENT; (ii) ANY LOSS OF REVENUES AND LOSS OF PROFITS, HOWEVER CAUSED AND, WHETHER IN CONTRACT, TORT, OR UNDER ANY OTHER THEORY OF LIABILITY, WHETHER OR NOT LICENSEE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES; (iii) ANY COST OF PROCUREMENT OF SUBSTITUTE GOODS, SERVICES, RIGHTS, OR TECHNOLOGY; (iv) LICENSEE’S RELIANCE ON THE LICENSED SOFTWARE; (v) ANY DIRECT DAMAGES IN EXCESS (IN THE AGGREGATE) OF $100; (vi) ANY MATTER BEYOND FLEXXBOTICS REASONABLE CONTROL; OR (vii) ANY DAMAGES FOR PERSONAL OR BODILY INJURY OR EMOTIONAL DISTRESS ARISING OUT OF OR IN CONNECTION WITH THIS AGREEMENT, ON ANY THEORY OF LIABILITY, RESULTING FROM THE USE OR INABILITY TO USE THE LICENSED SOFTWARE, (B) UNAUTHORIZED ACCESS TO OR ALTERATION OF YOUR DATA OR (C) ANY OTHER MATTER RELATED TO THE LICENSED SOFTWARE. THIS LIMITATION OF LIABILITY SHALL BE ENFORCED TO THE MAXIMUM EXTENT PERMITTED UNDER APPLICABLE LAW. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU IN THEIR ENTIRETY.

NO CLAIM ARISING OUT OF THIS AGREEMENT, REGARDLESS OF FORM, MAY BE BROUGHT AGAINST FLEXXBOTICS MORE THAN THE SHORTER OF ONE YEAR OR THE MINIMUM PERIOD ALLOWED BY LAW AFTER THE CAUSE OF ACTION HAS OCCURRED.

C.4 EXPORT.

The Licensed Software and Documentation may be subject to U.S. export control laws, including without limitation the U.S. Export Administration Act and its associated regulations, and may be subject to export or import regulations in other countries. Licensee and its Authorized Users shall comply with all such regulations and agree to be solely responsible for determining whether Licensee may export, re-export or import the Licensed Software and Documentation in a legally compliant manner. Licensee represents, warrants, covenants, and agrees not to, directly or indirectly, export, re-export or transship products, technology, or software, including, without limitation, the Licensed Software, in violation of any applicable U.S. export control laws and regulations or any other applicable export control laws of any country having jurisdiction over the parties, or the transaction contemplated by this Agreement. By using the Licensed Software, Licensee represents and warrants that Licensee, and its Authorized Users, are not located in, under control of, or a national or resident of any U.S. embargoed country or on the U.S. Treasury Department’s list of Specially Designated Nationals or the U.S. Department of Commerce Denied Person’s List or Entity List. Licensee will indemnify and hold harmless Flexxbotics from any and all claims, losses, liabilities, damages, fines, penalties, costs, and expenses (including attorneys’ fees) arising from or relating to any breach by Licensee or its Authorized Users of the obligations under this section. Licensee’s obligations under this section shall survive the expiration or termination of this Agreement.

C.5 MISCELLANEOUS.

C.5.1 Confidentiality. Information shared by the parties, or their Affiliates, under this Agreement will be deemed confidential if it is disclosed in any form or manner, marked as, or reasonably considered, confidential, and includes without limitation, the technology provided hereunder, trade secrets, documentation, and know-how, whether or not marked, designated, or otherwise identified as “confidential” (“Confidential Information”). Confidential Information shall not include publicly available or independently developed information. The receiving party of any Confidential Information of the other party agrees not to use said Confidential Information for any purpose except as necessary to fulfill its obligations and exercise its rights under this Agreement. The receiving party shall protect the secrecy of and avoid disclosure and unauthorized use of the disclosing party’s Confidential Information to the same degree that it takes to protect its own confidential information and in no event less than reasonable care. Confidential Information does not include Licensee’s name, logo, or public endorsements expressly authorized under Section A.2.5. After termination of this Agreement, each party shall return to the other party any Confidential Information of the other party received during the term of this Agreement. Notwithstanding the foregoing, the existence of this Agreement and the identity of the Licensed Software and the parties to this Agreement may be disclosed for business purposes by either party.

C.5.2 Federal Government End Use Provisions. The Licensed Software is deemed to be “commercial computer software” and “commercial computer software documentation” pursuant to DFARS Section 227.7202 and FAR Section 12.212, as applicable. The rights of the United States Government to use, modify, reproduce, release, perform, display, or disclose the Licensed Software shall be governed by this Agreement.

C.5.3 Governing Law and Venue. This Agreement shall be governed by and construed in accordance with the laws of the Commonwealth of Massachusetts without regard to its conflicts of laws principles. All disputes arising out of this Agreement shall be subject to the exclusive jurisdiction of and venue in the Federal and State courts within Suffolk County, Massachusetts, U.S.A. The parties expressly waive and disclaim the applicability of the Uniform Computer Information Transactions Act (UCITA), as may be adopted in any jurisdiction, and the United Nations Convention on the International Sale of Goods.

C.5.4 Severability. If any provision in this Agreement is invalid or unenforceable, that provision shall be construed, limited, modified or, if necessary, severed, to the extent necessary, to eliminate its invalidity or unenforceability, and the other provisions of this Agreement shall remain in full force and effect.

C.5.5 Assignment. This Agreement is not assignable, in whole or in part, by Licensee without the prior written consent of Flexxbotics. Any attempt at assignment by Licensee, including by means of merger, acquisition, operation of law or otherwise, that is not expressly permitted under the terms of this Agreement or that is done without such consent shall be null and void and of no force and effect.

C.5.6 Integration; No Amendment. This Agreement sets forth the entire understanding and agreement between Licensee and Flexxbotics. Except as otherwise expressly stated herein, no other terms or conditions and no modification, alteration, or amendment of this Agreement shall be binding upon Flexxbotics unless accepted in writing by an authorized officer of Flexxbotics.

C.5.7 No Third-Party Beneficiaries. This Agreement shall be binding upon and inure to the benefit of the parties hereto and their respective successors and permitted assigns and nothing in this Agreement is intended to or shall confer upon any other person any legal or equitable right, benefit, or remedy of any nature whatsoever.

C.5.8 Information for Communications. From time to time, information about your license key(s), the version of the Licensed Software, the operating environment and the language packs you have installed may be transmitted by the installed Licensed Software to Flexxbotics. This information allows Flexxbotics to be more efficient in their communications with you regarding software patches, critical bug fixes and technical bulletins. For example, by (i) downloading alerts about new releases or service pack availability directly to your server; and (ii) utilizing the user interface to send critical technical support notifications to you that are applicable to the specific installation of the Licensed Software running in your environment.

C.5.9 Updates to this Agreement. Flexxbotics may change the terms associated with its Software End User License Agreement at any time by updating this Agreement and posting it on the Flexxbotics website. Changes to this Agreement apply to any updates to the Licensed Software acquired or renewed after the date of modification. Such updates will apply only to new or renewed licenses, unless expressly accepted by Licensee for existing licenses.

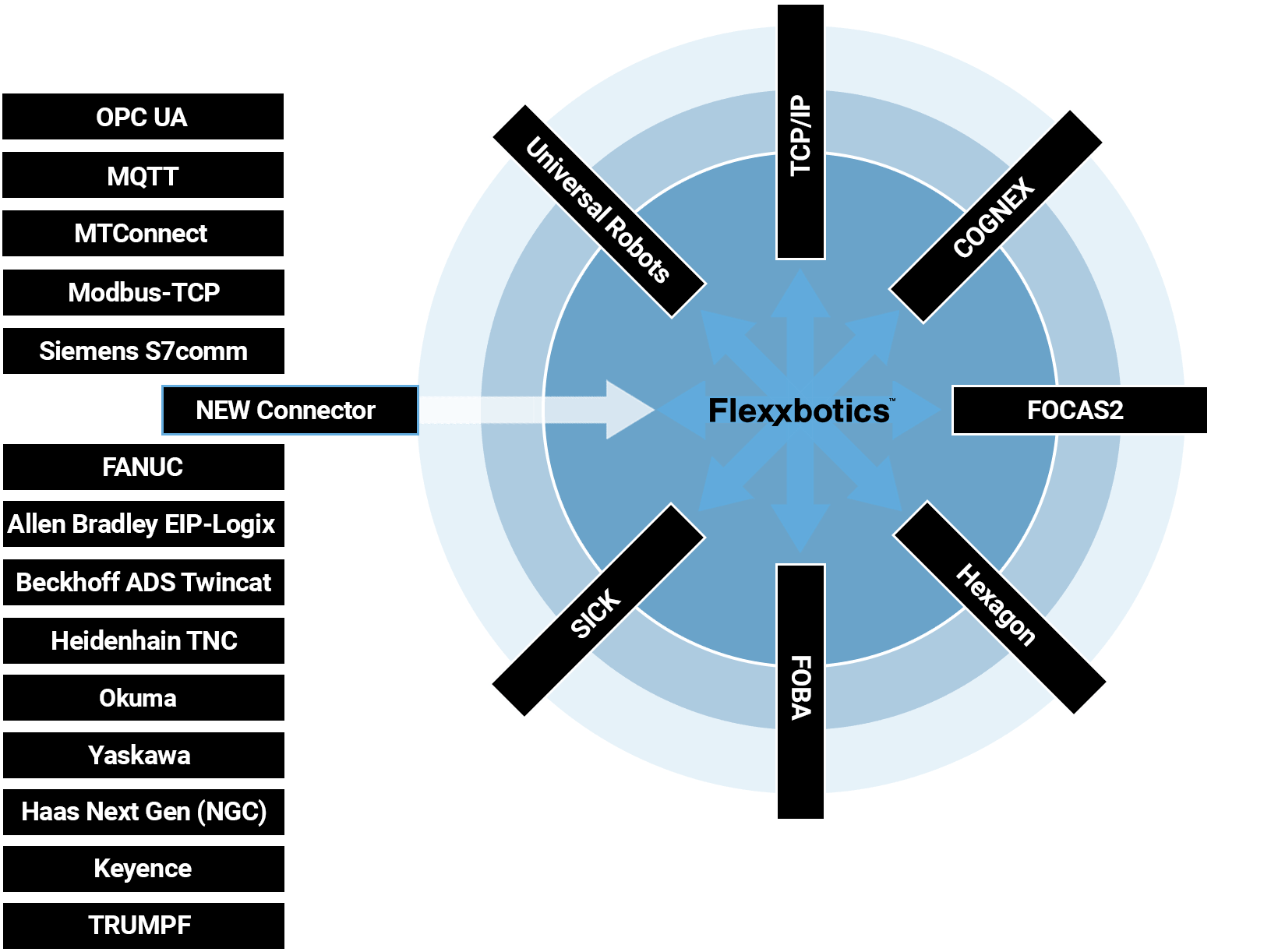

to create new connector drivers

to create new connector drivers