Compatible with:

Run your machine tending

operations lights out

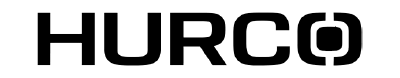

The FlexxCNC™ enables you to automate all aspects of your CNC. Execute G-Code, actuate vises / chucks / doors, initiate stop / start / wait cycles and connect to any other peripherals all through polyscope through the FlexxCNC™.

Run your machine tending operations lights out

The FlexxCNC™ enables you to automate all aspects of your CNC. Execute G-Code, actuate vises / chucks / doors, initiate stop / start / wait cycles and connect to any other peripherals all through polyscope through the FlexxCNC™.

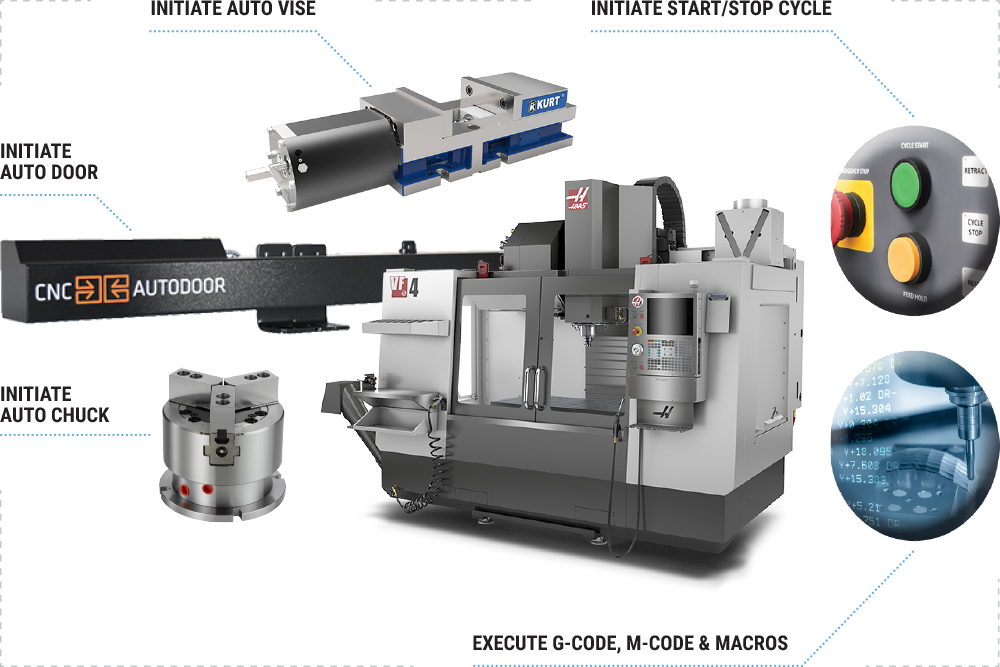

Standardize the solution

across your shop

The FlexxCNC™ is compatible with a majority of CNC machines giving you the ability to standardize this solution across your shop. Move your cobot and FlexxCNC™ from one machine to another as demand shifts or build your cobot fleet to service the variety of CNC’s on your floor.

Streamline with

machinists in mind

The FlexxCNC™ tool kit is built with machinists in mind. Everything from the dedicated I/O to direct where to wire your into your CNC/peripherals to using programming language in polyscope that coincides with your machine enables machinists to take on both the integration and operation of their cobot workcell.

Streamline with machinists in mind

The FlexxCNC™ tool kit is built with machinists in mind. Everything from the dedicated I/O to direct where to wire your into your CNC/peripherals to using programming language in polyscope that coincides with your machine enables machinists to take on both the integration and operation of their cobot workcell.

FlexxCNC™ helps you to:

Reduce Robot

Integration Time

Redeploy Your Robot

on Multiple Machines

Run Commands

to Your Machine

Simplify Your Robot

to Machine Operation

Read Our

RDS Case Study

Read about how we helped solve RDS’s

machinist labor shortage issues

FlexxCNC™ Financial

Justification Article

Read about the cost savings of integrating

the FlexxCNC™ into your CNC operations

What our customers are saying

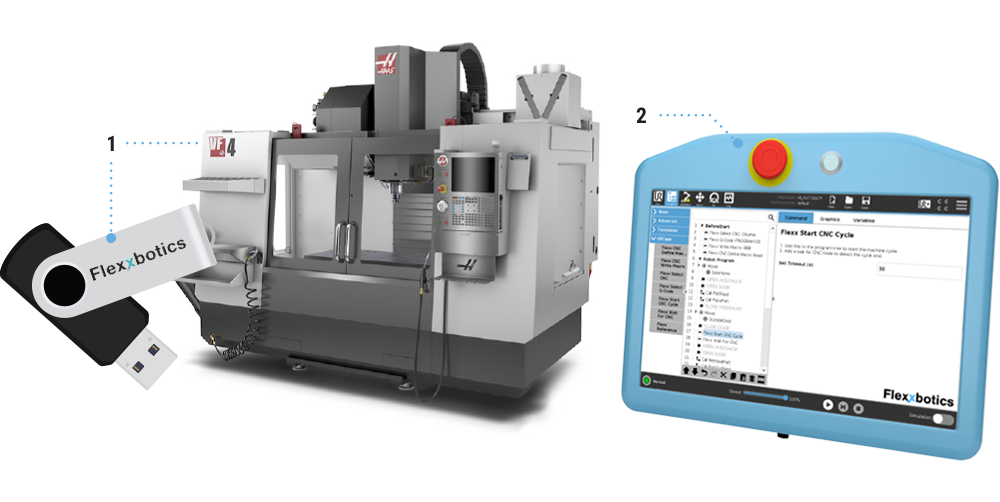

How FlexxCNC™ works:

Part 1:

Connect your cobot and machine to the FlexxCNC™ middleware

Part 2:

Wire to your peripherals

- Dedicated & labeled I/O

- Wiring kits & instructions to all peripherals

Part 3:

Build your program

- Upload the executable/configure server connection

- Build your program in polyscope using Flexx programming nodes

View all the

Compatible

CNC Machines

Learn more about the

compatible CNC companies

Read Our CNC

Machine Tending

eBook

Learn how to automate you

CNC with collaborative robots

Best in class interface giving you the ability

to automate all aspects of running a CNC

Load

G-Code

Cycle Start /

Stop Detection

Write

Macros

Control Peripherals

(Door, Vise, Chuck)

Programming

Templates

Multi-Op Robot

Automation

Standardized

Software

CNC Interface

Software Library

Technical Articles

FlexxCNC™ Financial Justification

12/4/2022

Machine Tending CNC Robots

2/28/2022

Machine Tending Robot Redeployment

Sep 2021

Connect A Cobot To Your CNC Machine

Feb 2021

Integration Guide | CNC Machine - Cobot

Feb 2021

FlexxCNC™

Specifications & Resources

Power: 120V AC (American Standard, outlet type: Type B NEMA 5-15)

Mounting: M6 mounting holes

Dimensions: 10″ x 8″ x 6″

I/O: DIO at 24V (Relay provided for non 24V integrators)

CNC Compatibility: Haas, Mazak, Fanuc, Okuma, Brother, Mitsubishi, DMG Mori, Siemens, Heidenhain & Hurco

Robot Compatibility: CB3 and E-Series

Connectors: (12) M12 DIO connectors, 1 USB, 2 Ethernet port, 1 Power entry module

How It Works

Download UR Cap

User Manual

FlexxCNC 1-Page

Financial Justification

Okuma User Manual

Fanuc User Manual

Haas User Manual

Mazak User Manual

Speak with an Expert

Frequently Asked Questions

Test

Test

Why is my UR program timing out?

When the FlexxCNC™ middleware isn’t able to send signals over ethernet to the UR Robot, the program will timeout. The node that is causing the timeout can us where the issue is. Learn more

Okuma server isn’t working

Issues related to the server come in two types: where the server crashes on running, and where the server does not respond to UR node commands. Learn more

G-code is stuck on an M00 or M0

This error often appears due to not enough “Cycle Start” and “Wait for CNC” pairs being present for the program being loaded into memory or currently running. Learn more

How do I wire my FlexxCNC™?

The FlexxCNC™ M12 connections are all similarly wired to have a 24V (volt) source, and 0V ground, and one or two signal pins. In this way, both sinking (NPN) and sourcing (PNP) signaling styles can be used. A normally open (NO) relay will be included in kits so that CNC’s with non 24V signaling can be triggered using the FlexxCNC™’s outputs. Find the wiring diagram here.

What power rating does the FlexxCNC™ use?

The FlexxCNC™ will draw no more than 12W (watts). The outputs provide 24V (voltage) signal, and the inputs detect a 24V signal. Learn more

Test

Test

What do I do if my CNC machine does not have an ethernet port?

You can still automate your machine! In this case, you will be using the Flexx CNC Start Cycle Node, and a Wait node, using the “Wait for ___” mode. Learn more

Do I need an executable to set up the FlexxCNC™?

The only interfaces that require an executable to be placed on the Machine HMI are the Okuma OSP300 and OSP200. Fanuc, Mazak, and Haas interfaces only require some settings changes outlined here.

How do I get my license key for the FlexxCNC™?

The best way to get your license key is to email us at support@flexxbotics.com with your company name and the serial number of the robot you will be using with the FlexxCNC™. Your robot’s serial number can be found by navigating to the installation tab, finding the URCAP dropdown, hitting the FlexxCNC™ tab, and then the Setup tab at the top. Below your activation key field is the serial number of your UR! Learn more

What type of I/O connectors does the FlexxCNC™ use?

What if I need additional I/O ports outside of the FlexxCNC™?

While expanding the M12 I/O ports is not possible at this time, the Flexx CNC does not interfere with or use any of the native UR DIO ports! Check the inside of your UR control cabinet and the DIO nodes in Polyscope to expand your DIO options. Learn more

LEARN MORE AND GET STARTED…

"*" indicates required fields

Flexxbotics values your privacy. Website terms and conditions.