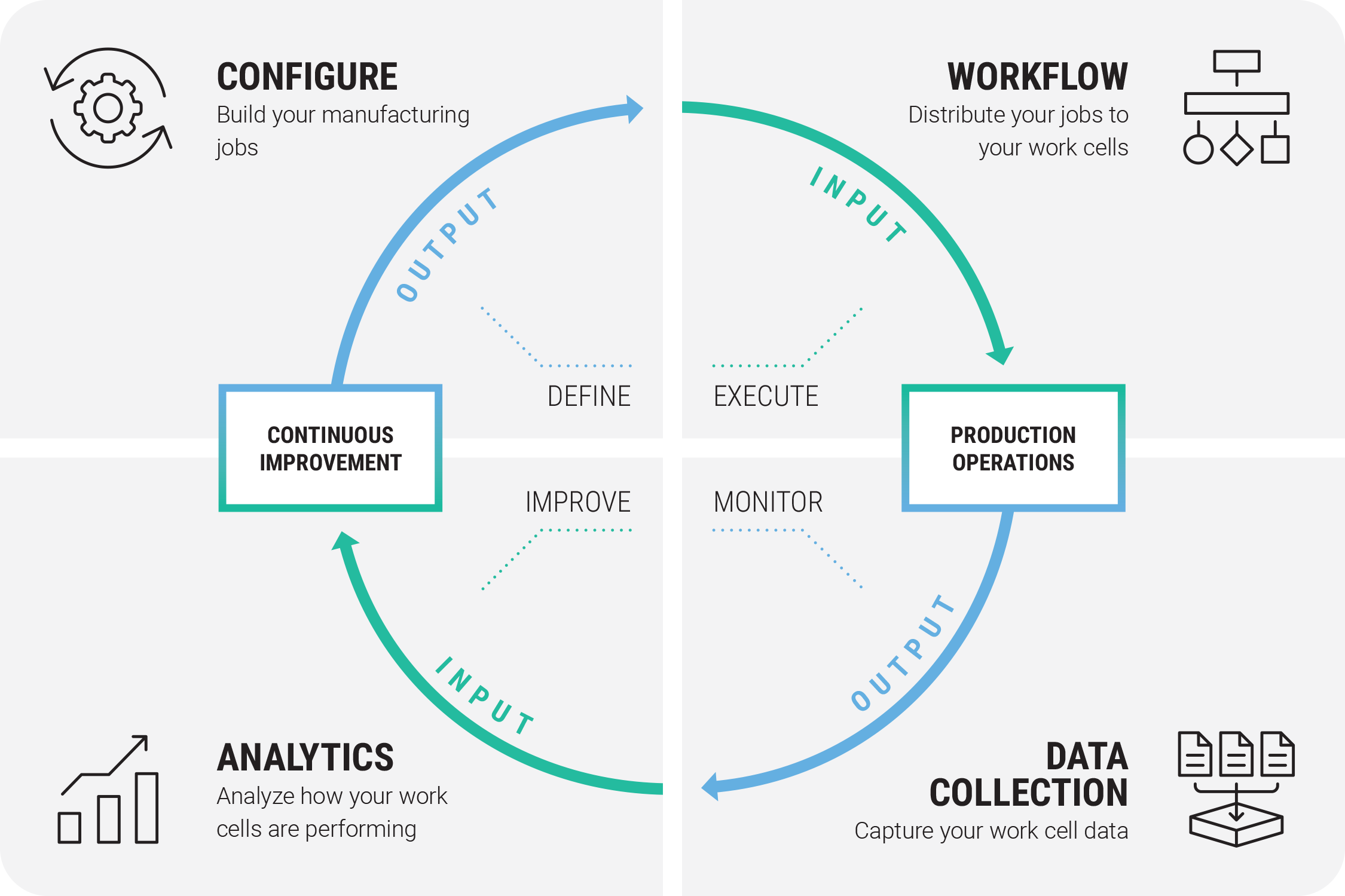

Configure

1. Install software and register workcell

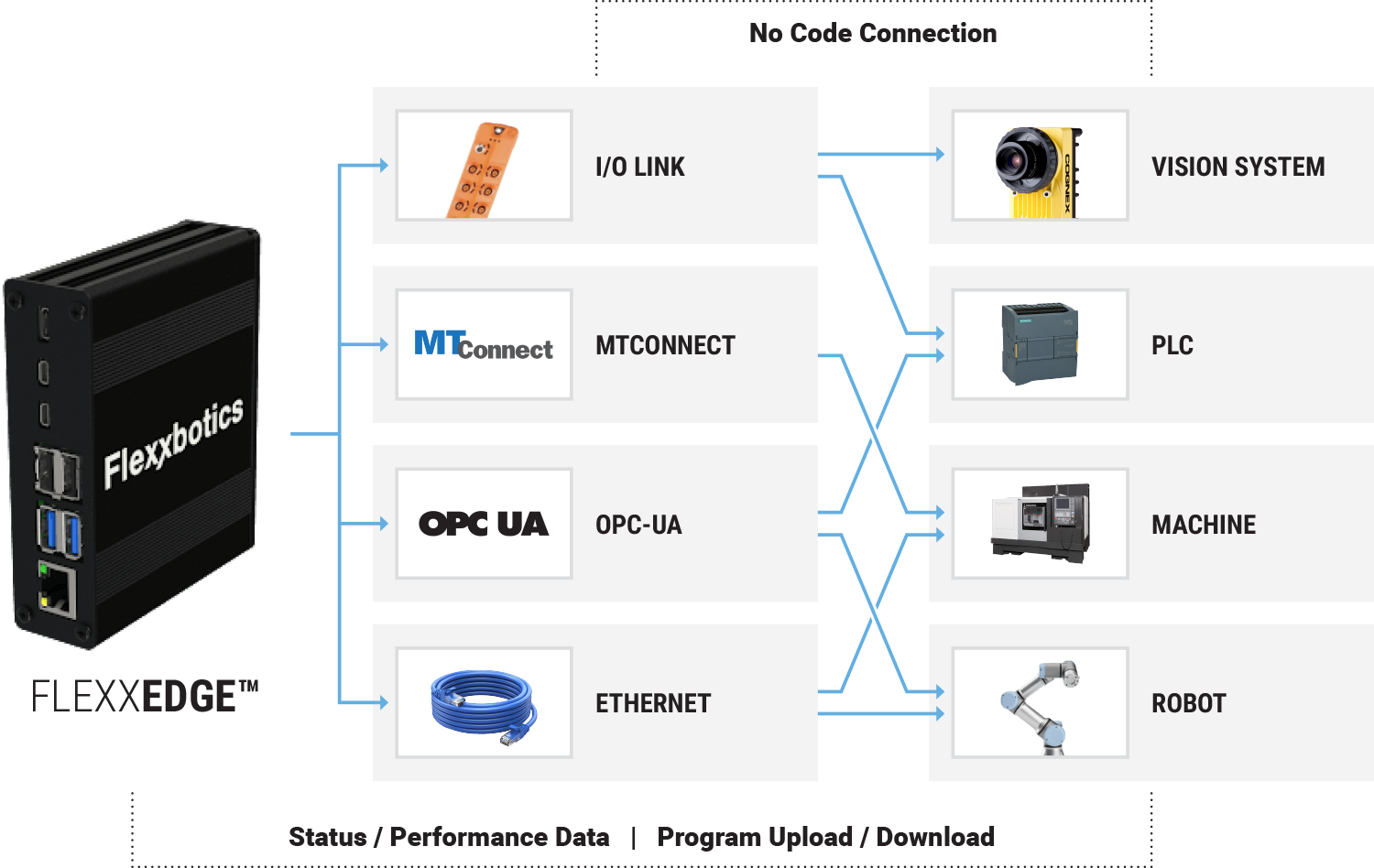

Software can be installed on existing PC or our out of the box FlexxEdge device.

2. Setup workcell device connections

FlexxConnect installs with a proprietary library of industrial device connectors. No devices? No problem. Our software fully supports manual data entry. See our device library.

3. Create a job workflow

Create a step by step workflow including modules such as work instructions, digital instruction sets, barcode scanning and many more! Assign the job workflow to a workcell and operators are ready to execute. Have existing materials? FlexxConnect comes will full no-code support to connect directly to your enterprise business system. See our modules library and business connector library.

Configure

1. Install software and register workcell

Software can be installed on existing PC or our out of the box FlexxEdge device.

2. Setup workcell device connections

FlexxConnect installs with a proprietary library of industrial device connectors. No devices? No problem. Our software fully supports manual data entry. See our device library.

3. Create a job workflow

Create a step by step workflow including modules such as work instructions, digital instruction sets, barcode scanning and many more! Assign the job workflow to a workcell and operators are ready to execute. Have existing materials? FlexxConnect comes will full no-code support to connect directly to your enterprise business system. See our modules library and business connector library.

Workflow

1. Operator sign in

FlexxConnect™ provides an operator sign in with role based access control. This provides ability to control tasks between operators as well as an audit trail as to who is performing the work.

2. Select a job workflow to run

Operators now have the ability to run the jobs built in the configure step. This reduces time and errors when gathering materials for jobs being run.

3. Step by step quality control verification

FlexxConnect™ provides gated workflow for your operators with active on-screen feedback. The software keeps a record of all events that occur during the workflow process.

Data Collection

1. Automatic data collection from connected devices

FlexxConnect™ automatically collects performance data from your connected devices. This includes information about:

- Status

- Part Counts

- Failure Counts

- Cycle Times

2. Manual data collection

If automatic data collection is not achievable, manual data entry is designed to be seamless. Operators can choose between different workcell statuses and reason codes for downtime. Part and failure counts can be easily tracked through batch part / failure count events with an easy big button interface.

Data Collection

1. Automatic data collection from connected devices

FlexxConnect™ automatically collects performance data from your connected devices. This includes information about:

- Status

- Part Counts

- Failure Counts

- Cycle Times

2. Manual data collection

If automatic data collection is not achievable, manual data entry is designed to be seamless. Operators can choose between different workcell statuses and reason codes for downtime. Part and failure counts can be easily tracked through batch part / failure count events with an easy big button interface.

Analytics

1. Understand problem workcells

FlexxConnect™ provides out of the box analytics as to give you visibility into low and high performing workcells.

- Utilization

- Yield

- Part Rates & Average Cycle

- Downtime Reasons

- Overall Equipment Effectiveness

2. Track improvements over time

The software allows you to look at performance analytics both on a snapshot and historical basis.

3. Setup condition monitoring

Condition monitors can be setup to automatically email escalations when performance metrics are out of specification.

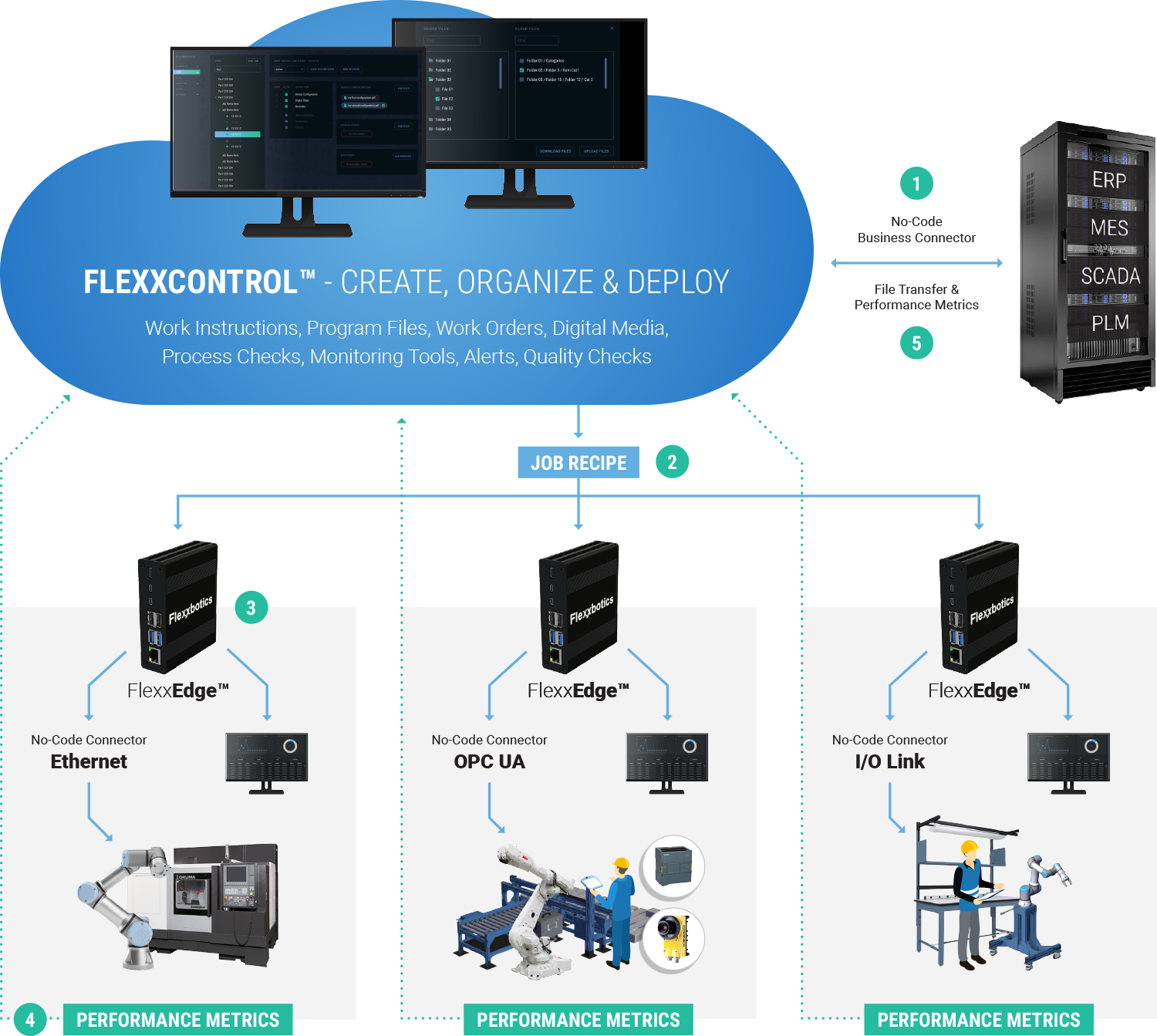

FlexxConnect™ Overview

1. Import existing files and programs from business systems or network drives with no code connectors

2. Build your manufacturing job recipe all in one location

Deploy your job down to your work cell to each FlexxEdge™. The FlexxEdge™ sends information directly to your equipment and displays gated step by step instructions for your operators

3. Capture work cell data either automatically from equipment or manually from operators. Analyze that data within FlexxControl™

Export your work cell data to additional business systems and keep consistent rev control of files/programs

FlexxConnect™ Process Control

1. Each job that is deployed to your work cells has a gated step by step process to guide operators on how to efficiently set up each job. Upload work instructions, create custom images/videos, embed downstream alerts, upload programs, and use barcodes to validate parts within assemblies

2. Each job completed comes with a full audit report that is uploaded to FlexxControl™. See who set your work cell, how was it set up and what rev all files/programs were on.

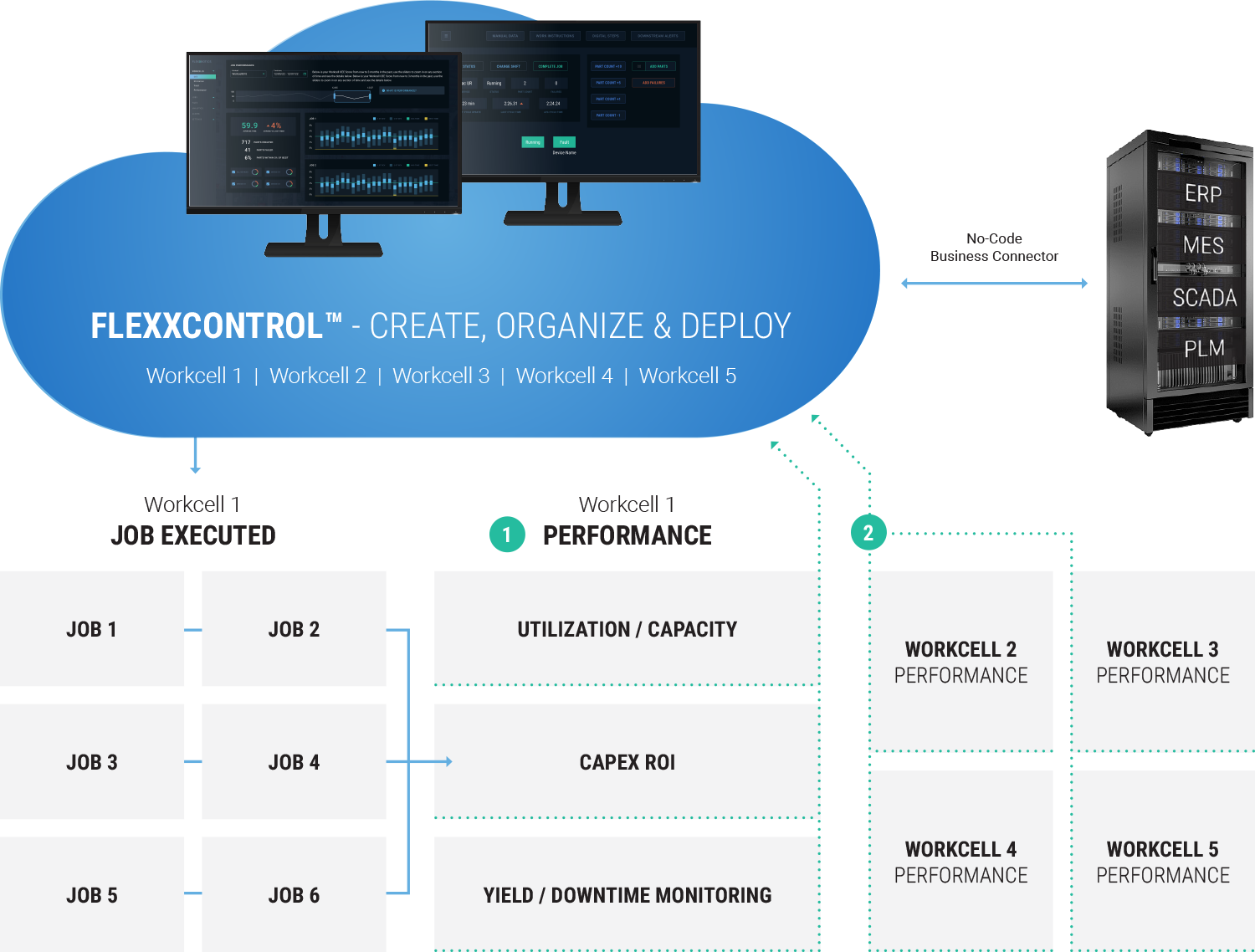

FlexxConnect™ Monitoring

1. Each work cell produces its own set of performance metrics. Quickly visualize how your work cell is performing with analytics such as OEE, Work Cell Costs, Utilization, Yield and many more

2. Since FlexxConnect™ is standardized across your floor all work cell data is uploaded to one location in FlexxControl™. Easily see facility performance, compare work cell performance and make your next decisions on capital equipment purchases

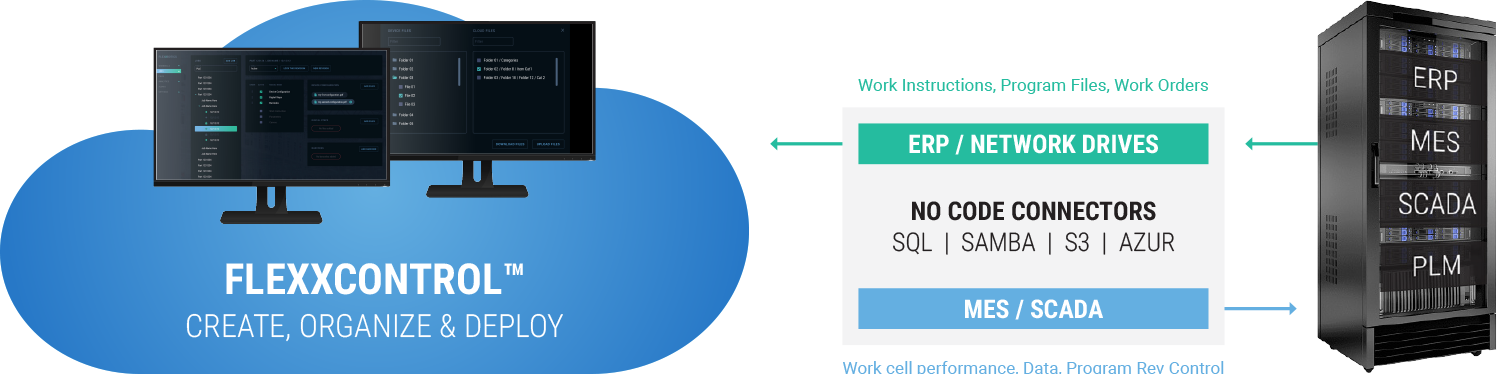

FlexxConnect™ Business System No-Code Connectors

FlexxConnect™ Device No-Code Connectors

Flexxbotics Security

At Flexxbotics, we understand the importance of protecting our clients’ information and data. That’s why ensuring the security of our software is one of our main focuses. We incorporate security considerations throughout the design and development process and strictly adhere to policies and principles prioritizing the security of our software.