FlexxConnect™ UR helps you

maximize performance

You’ve integrated your cobot and now you want to make sure you get the most out of it. How do you have instant access to performance metrics? How do you transfer ownership of day to day operations to my operators?

To maximize performance you need:

Real time access to cobot

performance work cells

To visualize and analyze historical

performance data

Ability to empower operators to share

ownership of cobot work cells

What is FlexxConnect™ UR?

FlexxConnect™ UR is a continuous cobot improvement platform that provides easy access to cobot insights and gives you the tools to enable your team to manage cobot work cells.

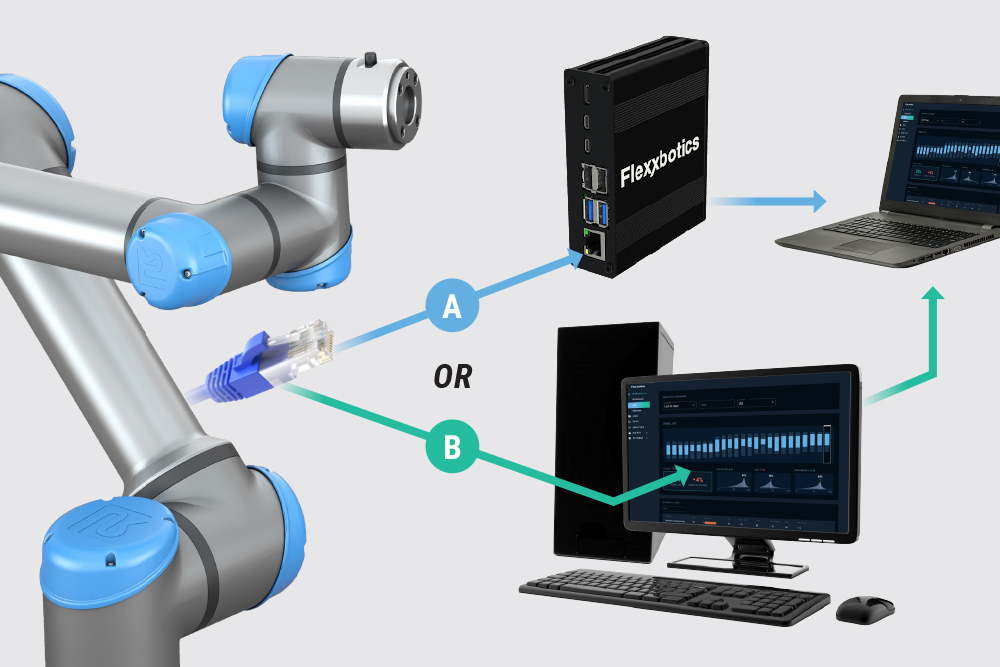

How to get started

Start with just one cobot. Either connect your UR over ethernet to an existing computer in the work cell or connect over ethernet to our FlexxEdge™ device. Match IP addresses and insert variables into your program.

Immediately start receiving contextualized insights on:

OEE

Utilization

Yield

ROI

How to get the most out of FlexxConnect™ UR?

Great! Now you have instant access to cobot performance insight. What do you do with that data? Continuously improve your cobot operations!

Use our cobot workflow creator to build cobot jobs with digestible digital videos, remote cobot program management, quality alerts and more. Deploy those workflows down instantaneously to your cobot work cells for your operator to run your cobot jobs. Use your data insights and feedback from operators to continuously improve your cobot performance.

Who is FlexxConnect™ UR for?

Operators

Upskilling your workforce to be able to manage your cobots

Automation Engineers

Simple step-by step digital instructions to transfer cobot operation to operators

Manufacturing Engineers

Gain detailed performance information to ensure high productivity

Operations Managers

Gain real-time insights into cobot production, to ensure operations run continuously

Executives

Get a high level snapshot of all cobot production, costs, and ROI

When is a good time to implement FlexxConnect™ UR?

Immediately. The sooner you start collecting the data from your UR the sooner you can optimize your cobot and processes.

Get insights as soon as your cobot is installed and see areas for attention such as setup, loading part trays, job changeover, cobot faults, operator faults, etc.

Benefits are multiplied as you expand your cobot fleet. A few extra seconds/minutes of production time per cycle can dramatically increase your profitability. The longer your team goes without insights into your cobot, the more money you could be leaving on the table.

Why FlexxConnect™ UR?

Higher Production

Lower Operating Costs

Increased Quality

Accelerate ROI

Upskill Workforce

Optimize Cobot Management

How to expand to FlexxConnect™ UR?

FlexxConnect™ platform is compatible to any equipment and work cell type. Expand to manual work cells, legacy equipment, and all types of automated equipment.

FlexxConnect™ can connect to existing business systems to push and pull information from these business systems to and from the work cell.

Manage data for entire facilities and easily transfer that information between your people, business systems and

work cells.