FlexxReference™ ensures that your robot

is never idle by giving you the ability to:

Easily repurpose a cobot from one work cell to another when demand changes

Get your work cell up and running within minutes after planned or unplanned downtime

Case Studies & Testimonials

Port Erie Case Study

Read how the FlexxReference™ shaped how Port Erie Plastics

utilizes their automation.

AIM Processing Case Study

Learn how a custom plastic injection molding company used a single cobot to automate multiple machines with a few clicks of PolyScope.

What our customers are saying

Check out the different variations of the FlexxReference™!

High Accuracy

Use 3 Flexx Features to create a Flexx

Plane with 3x increased accuracy

FlexxSwap™

Combine cobot redeployment benefits

with the arm tool innovation of Millibar

How It Works

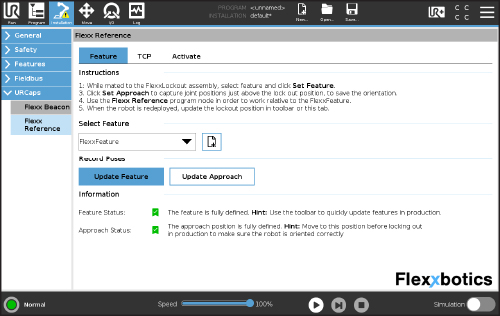

1. Set Your Flexx Feature

To set your first Flexx Feature (reference point) simply Free-Drive the UR into the Flexx Lockout Assembly (6-degree mechanical mating system).

2. Capture Your Coordinates

While in the Flexx Lockout, capture the coordinates with the click of a button in the Flexx Reference URCap Plugin. The Flexx Feature is automatically populated in the Flexx Reference Node, which is inserted into your program.

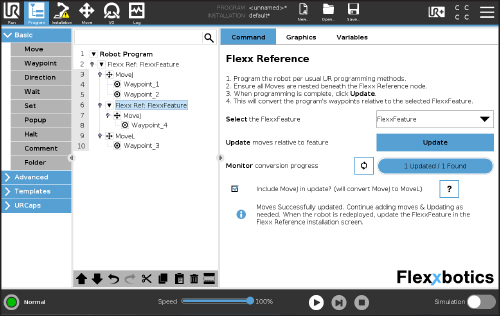

3. Update The Program

Program the robot as normal then click update program and all of your waypoints and moves will be converted relative to the captured Flexx Feature. The Flexx Feature is forever remembered in space and in your program.

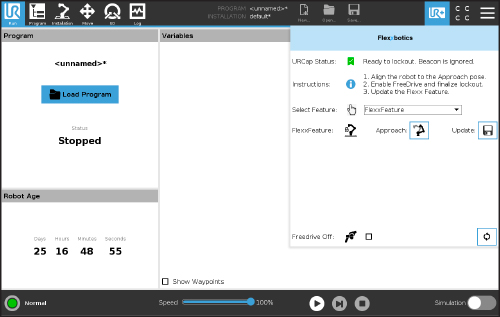

4. Recapture The Flexx Features

The user is now allowed the flexibility to move the robot or work station without the need of reprogramming or docking stations, simply re-capture the Flexx Feature and start the program.

Articles

Machine Tending Robot Redeployment

9/17/2021

Reducing The Technical Barrier of Robot Installation

9/12/2021

Robot Utilization for Collaborative Robots

9/11/2022

Robot Redeployment Using Robot Offsets

8/24/2021

Financial Benefits of Mobile Cobot Redeployment

5/15/2020

FlexxReference™

Specifications & Resources

Standard Accuracy: ±1mm from the TCP

High Accuracy: ±0.1-0.5mm from the TCP

Locking Time: 1 -2 Minutes

Material: Aluminum

Robot Compatibility: UR E-Series and CB-Series Robots

3rd Party End Effector Compatibility: All UR+ End Effectors and others

Lead Time: 1 Week

How It Works

Download UR Cap

User Manual

Pallet Routine

1-Page PDF

FlexxSwap 1-Page

High Accuracy 1-Page

Speak with an Expert

Frequently Asked Questions

Test

Test

What is a robot reference frame?

Robot’s are generally programmed relative to their base. This means every waypoint and move is taught relative to the base. If you move the robot base your moves and waypoints will move proportional to the distance the base has moved. You can use alternate frames such as reference points. These reference points give what are called real world coordinates to a robot so they can have a better understadning of it’s location.

What is the accuracy of FlexxReference™?

FlexxReference™ has two accuracy versions. The standard FlexxReference™ has an accuracy spec of +/- 1mm from the TCP. The High Accuracy FlexxReference™ has an accuracy spec of +/-0.1- 0.5mm from the TCP. The High Accuracy spec is based off a normal distribution with the median being 0.3mm and a standard deviation of 0.1mm.

Do I need to put the robot in the same place when using the FlexxReference™?

The simple answer is no. FlexxReference™ uses hardware and software to offset your program without the need to dock your robot. We suggest you put some markers on the floor to place the wheels of your robot in a relatively similar spot for robot waypoint reach concerns. We also suggest using the align feature of FlexxReference™ which creates a waypoint for your robot to go to about 6 inches above your lockout point. This assist your operator with locating a relatively close location of where the robot needs to be positioned.

Test

Test

How many degrees of freedom does the FlexxReference™ offset?

FlexxReference™ offsets a programs moves and waypoints in 6 degrees of freedom or X,Y,Z, Rx (Roll), Ry (Pitch) and Rz (Yaw).

What is the functional difference between the standard and high accuracy FlexxReference™?

The standard FlexxReference™ uses one station interface piece to lockout to. The High Accuracy FlexxReference™ uses three (3) station interface pieces. You place one station interface as your origin and you place one station interface piece on the x-axis and one station interface piece on the y-axis. Start by locking out the origin station interface piece and then follow by locking out the x-axis and y-axis station interface pieces.

I don’t plan on redeploying my robot. Is FlexxReference™ still a good investment?

Yes! We have many customers that use FlexxReference™ for fixed robots that have dynamic fixtures or part trays coming in and out of the cell. We have customers that have machines/stations that run both automated and manual and the robot needs to be brought in and out of the work cell. Finally we have customers that use exclusively for maintenance of the robot or work cell. Larger programs can take a week to reset without FlexxReference™ and can be a significant cost if not considered when setting up the robot the first time around.

LEARN MORE AND GET STARTED…

"*" indicates required fields

Flexxbotics values your privacy. Website terms and conditions.