Flexxbotics

Robot Machine tending

Advanced Robotic Machine Tending

for Continuous Operations

FLEXXBOTICS CAPABILITIES

BASIC

- Load/Unload Parts

- Cycle Start

- End Cycle Detection

- Peripheral Control

STANDARD

- Status & Downtime

- Fault Detection

- Alerts & Escalations

- Part Count and

Cycle Time

Advanced

- In-line QC with SPC

- Real-time Offset Updates

- Defect Sorting, Count & Reasons

- Yield, Utilization, OEE and more

BASIC

- Load/Unload Parts

- Cycle Start

- End Cycle Detection

- Peripheral Control

STANDARD

- Status & Downtime

- Fault Detection

- Alerts & Escalations

- Part Count and

Cycle Time

ADVANCED

- In-line QC with SPC

- Real-time Offset Updates

- Defect Sorting, Count & Reasons

- Yield, Utilization, OEE and more

Continuous Operations

More

Capacity

Continuous Operations

More

Capacity

GREATER

EFFICIENCY

INCREASEd

PROFIT PER PART

GREATER

EFFICIENCY

INCREASEd

PROFIT PER PART

Talk with an expert to help identify potential robotic automation opportunities

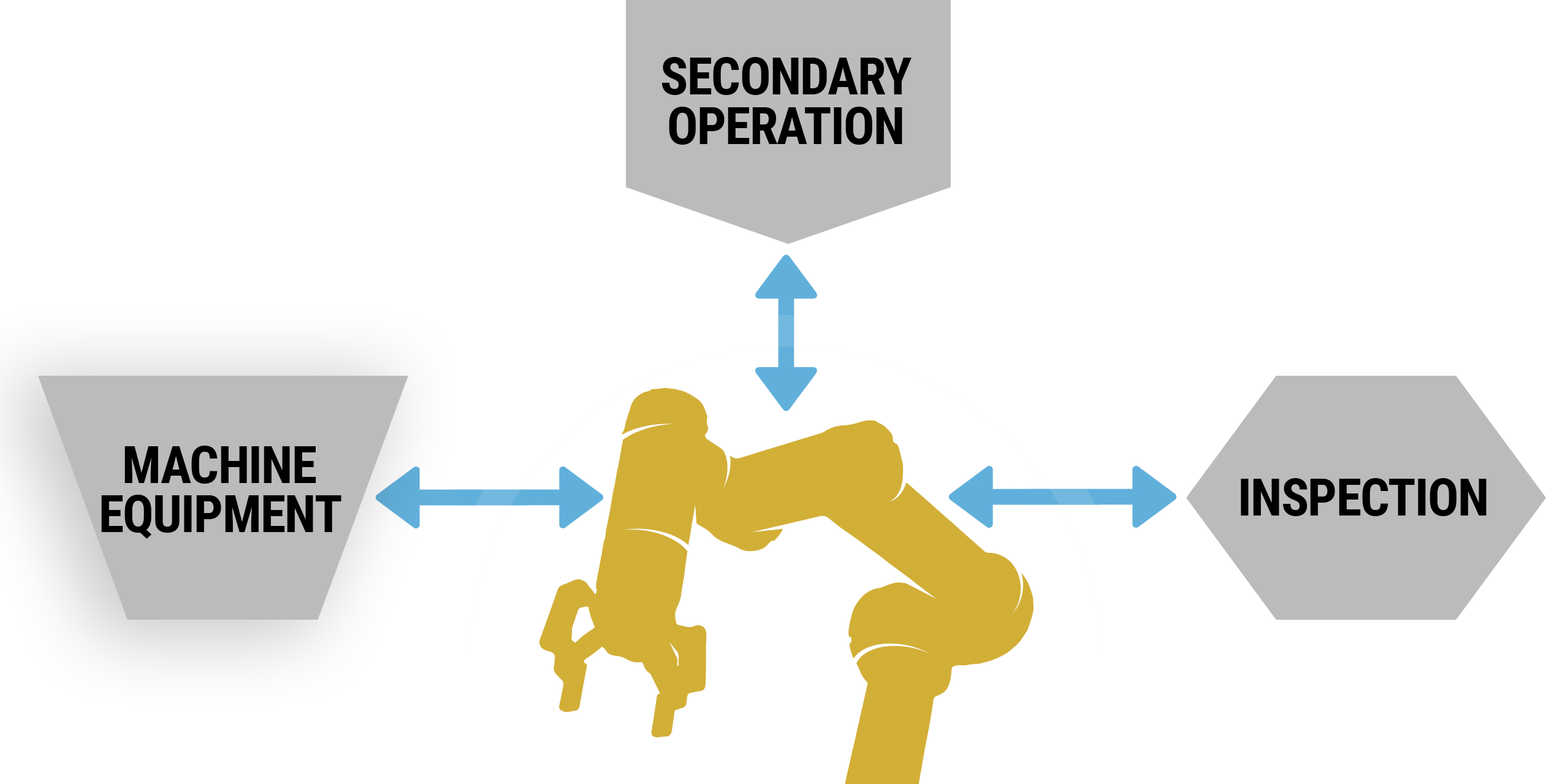

Have your robots tending your machines with communication, coordination, and control of all your automation machinery, equipment and systems

We work with All These Machines

And More

Breakthrough

Innovation

Our unique FlexxCORE™ technology

seamlessly connects and coordinates robots with existing factory automation equipment, IT systems and people

ENABLE ROBOTIC MACHINE TENDING

at scale or One Workcell at a Time

Our Customers

NEW WHITE PAPER

Autonomous Process Control using Robots & Automated Inspection in Manufacturing

LEARN MORE AND GET STARTED…

"*" indicates required fields

Flexxbotics values your privacy. Website terms and conditions.