By: Flexxbotics August 2021

Robot Redeployment

How to Easily Redeploy Your Cobot for Multiple

Jobs Using Robot Offset Systems

You may have seen plenty of studies describing how beneficial collaborative robots can be for small and medium businesses. You’ve seen how they can bring higher productivity, solve labor shortages, and have a short return on investment. However, a short return on investment isn’t always possible especially if your task doesn’t run full time. What can you do to still make the most of your cobot? Let’s talk about collaborative robot redeployment

What Is Robot Redeployment?

Ease-of-use and flexibility are two of the most discussed advantages of collaborative robots especially when comparing them to industrial robots. Those two characteristics are why it is possible to move the robot to different stations during the day. This is what robot redeployment means. Robot redeployment can help you to maximize business gains, achieving high cost-efficiency and fast ROI. Now, making most of your collaborative robot is the goal but is it as easy as it seems? The answer is that it can be as long as you use a good offset method.

Why Bother About Robot Offset?

Being able to redeploy your robot needs a certain strategy and method. The goal is to be able to move the robot back and forth at a station without having to reprogram it. To make sure the robot doesn’t need to be re-programmed, its position needs to be perfect or the program needs to adjust to its new position. This is when we talk about robot offset.

This approach is based on calculating the difference between the joint positions of the robot before and after the move. Then, using kinematics, an offset (small position change) can be applied to every robot position. There are many ways to re-position the robot at its place, but not all methods are equal in terms of ease of use, accuracy, and price.

Ease Of Use:

To maximize productivity, redeployment has to take as little time as possible. It is desirable for the process to take minutes, not hours, and be simple enough for non-technical staff to perform it. This way you get back to production faster!

Accuracy:

Ease-of-use shouldn’t however affect the accuracy, which is another important component of redeployment. An effective cobot redeployment needs to balance these two; trying to achieve high mobility without any sacrifices in precision.

Cost:

The cost of the redeployment solution also is important to consider to get a fast ROI. You need to determine what are your specific needs for your cobot application. Ask yourself these questions:

– How frequent the redeployment should be for a good ROI?

– What are the required levels of precision/accuracy of my tasks?

– What is my budget?

Which Robot Offset To Use?

There are different ways to find, calculate and apply robot offsets. When it comes to choosing an offset technique that fits your needs, there are three main methods or technologies available:

– Mechanical Robot Offsets

– Visual Robot Offsets

– Software + Mechanical Robot Offsets

Mechanical Robot Offset Systems

The most common idea to get the robot offset is to use a mechanical mechanism like a pining system. You might find it easier to simply have a fixture mechanism that will reposition your robot at the same place. But, designing and manufacturing a precise enough system often ends up being more difficult than originally expected. You also need to think about how this repositioning will translate into the program itself!

A mechanical do-it-yourself offset system will present tolerance stack-up issues. For example, a displacement of 1-2 mm in a pinning setup can displace individual waypoints 5-10x that amount. So designing your own mechanical fixtures will end up being more complex if done the right way for high accuracy. It will also require qualified engineers to deliver the project.

Visual Robot Offset Systems

The visual offset method relies on using a camera combined with special tags to reference the robot program. The relative position of the camera to the tag is what will get the difference between before and after.

As the visual system resolution limits its precision, less accuracy is one of the main weaknesses of this offset method. Moreover, vision systems are very sensitive to variations of lights and it can be an issue in a manufacturing environment. Finally, the cost of a vision system is often on the high side.

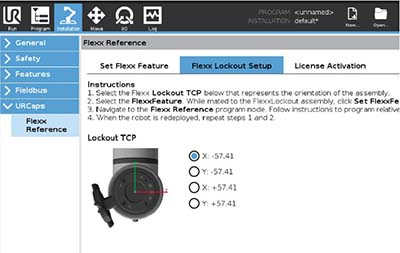

Software + Mechanical Robot Offset Systems

There is an alternative method that consists in combining a software layer with a unique mechanical fixture device. This combination helps to achieve the highest levels of accuracy and simplicity. The software component makes sure to handle any slight variation and eliminate to the maximum the need to adjust the robot program.

As an example, Flexxbotics has developed such a system for Universal Robots. Flexx Reference uses a precise lockout designed to make repositioning quick and simple. It allows you to program multiple reference points around your workstation, minimizing the redeployment time from hours to minutes.

Make the most of your cobot

Maximizing your robot redeployment is the reason why cobot redeployment should interest you. You’ll then need to choose the right offset method to meet your specific needs and expectations.

Each offset method has its own strengths and weaknesses. You should aim for a balance between simplicity, accuracy, and cost depending on your application needs.

Robot redeployment can help you maximize your manufacturing productivity and enable an aggressive robot ROI. Read more in our article the financial and operational benefits robot redeployment can provide you here.