By Flexxbotics: 12/4/2022

FlexxCNC™ Financial Justification

I’m Ready to Automate my CNC, now what?

So you’ve taken the plunge into automating your CNC machine. You’re tired of the lack of machinist labor and your current team is completely strapped keeping up with demand. Overall this is a smart move and your operations will benefit very quickly from the choice to switch to automated CNC’s. There are some things you need to know when kicking off an automation project, which can be reviewed in our article here. Having a solid interface between your CNC and robot is essential to a successful automation installation. Let’s run through your options and how each one generally works.

There’s generally three options for interfacing your robot to your CNC;

– Using Third Party Integration Services

– Do It Yourself (DIY) Integration

– Productized Robot to CNC Interface (FlexxCNC™)

When evaluating each of one these methods it’s important to understand the:

– Time it takes to execute

– Downtime associated

– Functionality you obtain

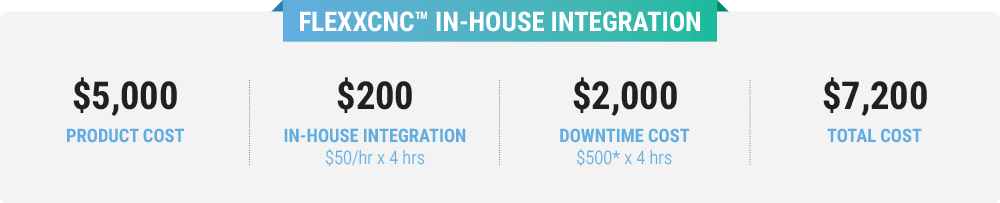

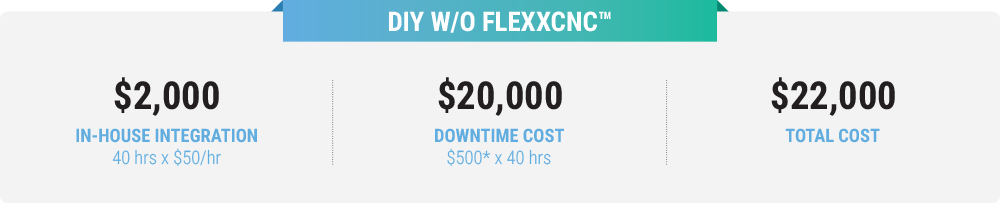

FlexxCNC™ Integration Cost Savings

The first and most straightforward justification for a CNC to Robot interface is the time x cost savings tied to rapid integration of your robot. Flexxbotics FlexxCNC™ interface touts the total integration time to interface your robot to your CNC is 4 hours or less. Traditional integration on average takes 2 days or 16 hours. If you’re planning on doing it yourself make sure to set aside 1 week to complete and that’s if you’re experienced with Systems Engineering. If you’re not, we suggest staying away from the DIY method. The “cost savings” quickly add up to internal costs, downtime and overall headaches.

To be clear, when we say interfacing we mean the interfacing integration only of your robot to your CNC. There are other integration costs associated with a robot integration including peripheral installation, part in-feed and out-feed assembly/integration and general robot programming/training. In this justification exercise, we are only focusing on the interfacing portion.

So let’s play this with the total cost associated with all three methods.

(Average Output/Hours = $500/hour)*

It’s clear to see the cost savings associated using the FlexxCNC™ vs traditional integration or DIY.

An added bonus to using a standardized interface is the additional automation output (labor reduction costs) you receive. You gain 12 additional hours over traditional integration and 36 hours over DIY, which translates to $300 and $900 labor savings respectively.

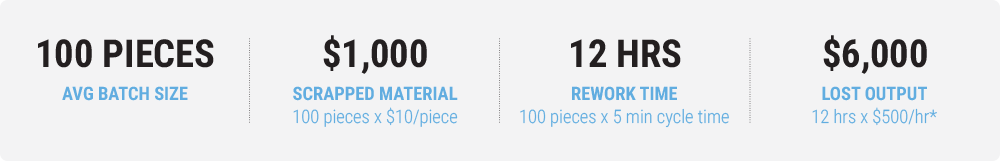

Fully Automated CNC

One significant and unique benefit of using the FlexxCNC™ is the ability to command the CNC to execute g-code, m-codes and macros through the robot. Any CNC machinist knows macros are essential when accounting for tool wear offsets on your g-code programs. The FlexxCNC™ gives you the ability to automate sending these macros from the robot to the CNC giving you true lights out manufacturing of your unattended CNC. The alternative is automating without using macros leaving you exposed to quality events usually resulting in scrapping our reworked parts. From our experience an event like this occurs once a month with an interface method that doesn’t allow the ability to utilize macro loading on the CNC. A quality event cost can then be calculated using the following assumptions.

Your total costs associated with this quality event would then be $7,000. Extrapolate over 12 months and you have $84,000 in lost output. Every facility of course is different so use your own numbers, but it’s clear even one quality event is detrimental to your CNC’s output.

Standardizing your Automated CNC Operations

Great, you’ve integrated your robot! The hard part is done right? Well not exactly. You still need to have a plan for operating your automated CNC work cell. So what’s the ideal way to manage your automated work cells? First is standardizing the way you program your robots. Using the FlexxCNC™, allows you to use the same digestible program nodes and structures allowing your machinists to easily grasp programming the robot and translate training and knowledge across all of your automated CNC’s despite the brand or controller. Trust us when we say, empowering your machinists to manage your robot work cells will be the best automation investment you make next to the robot itself.

The second benefit of the FlexxCNC™ is the ability to do both single operation and multi operation CNC jobs. The FlexxCNC™ can run multiple g-code programs in sequence on your CNC unattended and without having to alter any of your existing g-code. This allows any skilled level operator to manage both the machine and robot with less interruptions, downtime and programming.

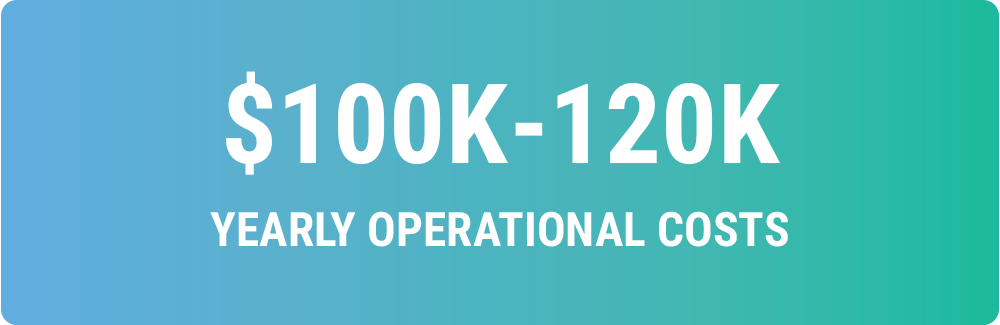

So how do you tangibly calculate the cost savings associated with these standardized operations? We compare the time it takes to program and setup the robot with the FlexxCNC™ interface and without with a few assumptions.

So all in all it seems that the way you integrate and utilize your robot to CNC interface is the most crucial aspect of any CNC automation project. Your total one time cost savings can range from $12k-$14k and yearly operational costs can range from $100k-$120k per year greatly impacting your CNC operational equipment effectiveness (OEE). The ROI is clear with the FlexxCNC™ and if you’re in the midst of conducting an CNC automation integration reach out to us to learn more!

If you would like to talk with a salesperson for an official quote

on the FlexxCNC™ reach out to sales@flexxbotics.com