FlexxConnect™ helps you improve CNC work cell

utilization, efficiency and quality, leading to:

Faster Capital Equipment ROI’s

Reduced Scrap / Rework

Higher Output

Higher OTD / Better Customer Satisfaction

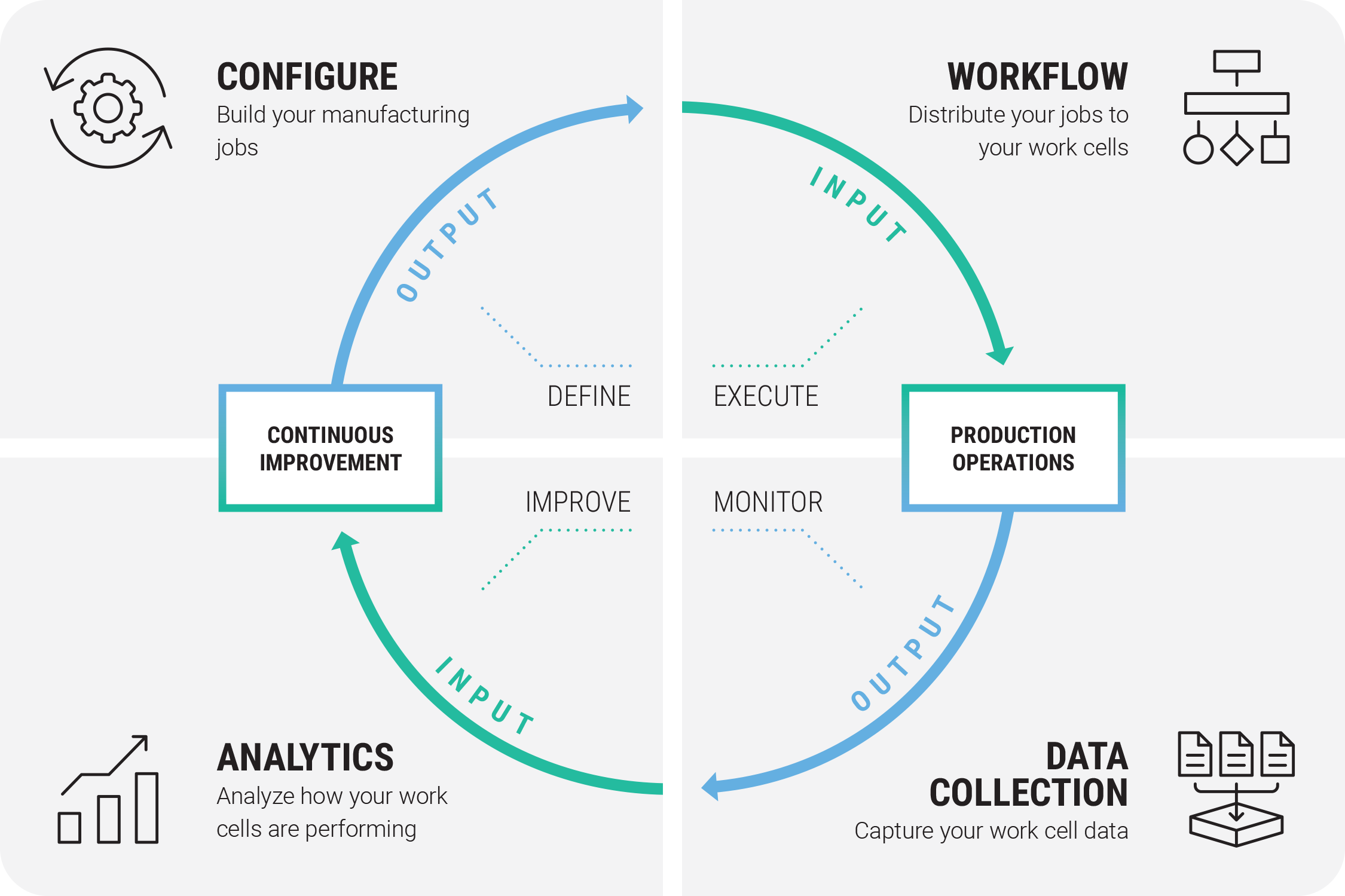

FlexxConnect™ Four Pillar Continuous Improvement Process

FlexxConnect™ is the only platform that converts work cell data into direct process improvement changes and provides the tools to execute and monitor how those changes effect your factory performance! We provide metrics that matter. This is done through the FlexxConnect Four Pillar Continuous Improvement Process.

Configure

Configure jobs with existing business system material such as tooling instructions and g-code programs. Connect to your work cell with no code industrial protocol and create a fully connected cell and job in less than an hour.

Configure

Configure jobs with existing business system material such as tooling instructions and g-code programs. Connect to your work cell with no code industrial protocol and create a fully connected cell and job in less than an hour.

Workflow

Level up your operators by giving them the ability to run even the most complicated jobs with simple and straightforward workflows. Reduce complexity by automatically uploading and downloading programs to your CNC’s and robots. Have the confidence that everything will run smoothly, every time.

Data Collection

Automatically collect performance data from your connected robots and CNC’s through our FlexxEdge device. Always know how your CNC cell is performing and maximize utilization by recovering from downtime immediately.

Data Collection

Automatically collect performance data from your connected robots and CNC’s through our FlexxEdge device. Always know how your CNC cell is performing and maximize utilization by recovering from downtime immediately.

Analytics

Out of the box analytics that give you true visibility into how your workcells are performing and how to make improvements. We provide metrics that matter. Upgrade to advanced analytics through our partnership with Datanomix.

FlexxConnect™ enables you to:

Easily Capture Data

Easily capture data from any type of work cell; manual, legacy equipment, new equipment or custom equipment

Analyze Data Efficiently

Analyze data in digestible, contextualized and relevant dashboards

Configure Process Control

Configure process control procedures with no code business system connectors

Boost Performance

Use proprietary continuous improvement metrics to boost work cell performance repeatedly

Easily Scale

Start with as little as one manual work cell and easily scale

Technical Articles

Cybersecurity Best Practices in Manufacturing

August 2021

Pragmatic Digital Transformation

Jul 2022

Optimizing Work Cell Management For Lean Manufacturing

June 2022

Industries

Applications

We Are Here To Help!

FlexxConnect™ pricing comes with

full support and integration assistance.

Don’t see a device, module or business

connector in our library? We’ll work with you!

Flexxbotics is equipped with application

specialists who can work directly with

our engineering team to meet your needs.

Scale As You Need!

FlexxConnect™ pricing allows for scaling at your own pace.

We understand digital transformation is a difficult process

that takes time to implement. We want to help you succeed.

Start with a trial unit to get started!