Integration Guide | CNC Machine

Loading With A Collaborative Robot

If you’ve never automated a CNC machine loading process, all the steps may not be obvious. CNC machine loading is the process of feeding materials into a CNC machine. This process is typically repetitive and mundane. As a result, CNC machine loading is often a prime candidate for automation because of its competitive advantages. This article contains a brief overview of some major components and considerations to integrate a CNC machine loading system.

Major Components of CNC Machine Loading System

Robot

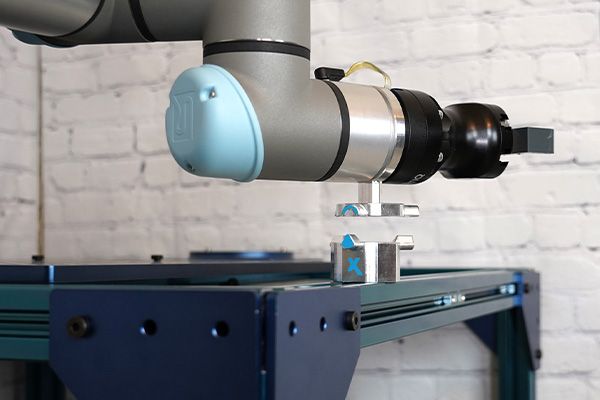

Of course, the main component of a CNC machine loading system is the robot. The robot is responsible for carrying out the systematic loading and unloading of material from the CNC machine. Its advantages over an automated feeding system [link to article 01] are its flexibility and the possibility of redeploying it as a tool on multiple machines.

While comparing all types of robots isn’t the scope of this article, it is common to use collaborative robots for this task. Universal robots have proven time and time again that they are a great solution for CNC machine tending due to their flexibility, ease of programming, and safety features. Read more about the advantages of using a cobot for CNC machine tending here!

Tooling

Tooling, sometimes called the end-effector of end-of-arm tooling, is the component that manipulates the workpiece, like grippers, suction cups, electromagnets, and more. It is a critical component of a machine tending system. Choosing the right tooling should consider all the different machining steps and part setups.

Base

The robot needs to be mounted reliably and sturdily on a base. There are stationary bases such as pedestals and mobile bases. Mobile bases can be manual or automated and allow easier robot redeployment between workstations.

Whichever you choose, you must make sure the robot will be steady enough to stay precise and repeatable during production. If you want to know more about the basis of robot installation for CNC machine tending, read this article.

TIP

When installing the base or redeploying it in front of another CNC machine, having a referenced program is important to save re-programming time. Mechanical machine reference tools like the Flexx Reference allow any operator to conduct a robot redeployment efficiently. It uses an intuitive interface and locking mechanism to let the robot know its position in reference to the CNC machine.

Automated Vises

Vises maintain the parts in the CNC machine during machining. In a traditional CNC machine, those will be manual vises. However, when integrating a robot, the opening and closing of those vises need to be automated. This will ensure minimal operator interaction and have a system that will be autonomous. The best way to automate the vise is to invest in an automatic vise, either hydraulic or pneumatic and use a robot signal.

Door Systems

The CNC door will need to open and close automatically to achieve unattended operations. Although we sometimes see the robot arm open and close the door, this isn’t the best automation method because it reduces the robot production time. The best installation you can have is an automated door system that can receive a robot signal.

Robot-to-CNC Connection

Establishing communication between your robot and your CNC machine is necessary to optimize your workflow. Then, your robot can send M-code/G-code to the CNC machine, letting it know to execute its tasks. But is it as easy as connecting your robot to your CNC?

Unfortunately, there aren’t easy ways to interface between your robot and CNC machine. Many different CNC interfaces exist, so finding a standard solution that can work in most cases has always been a big challenge in the industry. This leads to frustrations for manufacturers and lost opportunity for optimization.

Tip

From experience, we recommend using the robot as the server of the system and the CNC as the client. It means that the robot will send the G-code/M-code signals to the CNC. The robot, along with 3rd party products designed for the application, will often have an easier to program UI than the CNC controllers. This setup will also replicate the operator-CNC interaction, which is already proven to work well.

Moreover, manufacturers often have multiple CNC brands on their shop floor. So when investing in a machine tending robot, the redeployment on more than one machine can be challenging. So up to now, a custom integration needed to be done each time you needed to integrate your UR robot to a new CNC machine which is costly and complex.

This is when Flexx CNC comes into play. This new product from Flexxbotics finally offers the potential to standardize the integration between a UR robot and different CNC machines. It includes a standardized hardware and software interface for several major CNC brands, including:

The Flexx CNC Interface is a standardized middleware and URCap designed to make a Universal Robot easily communicate with multiple CNC machines. This new device centralizes the control of all the elements discussed above (G-code/M-code, vises, doors) through the middleware.

It can unlock several capabilities for manufacturers, including robot redeployment and the opportunity for lights out manufacturing. It also helps users to avoid costly custom integrations between robots and CNC machines.

Find Your CNC Machine Loading Solutions

There are plenty of options and configurations available to manufacturers for CNC machine tending solutions. These solutions come from 3 types of providers: integrators, do-it-yourself solutions, and off-the-shelf CNC automation solutions. So which one is right for you?

Integrator Solutions

Integrators are industrial providers that offer a wide range of services, including custom robot integrations. While an integrator may provide a solution for the communication between your UR robot and CNC machine, it will likely be a custom solution that won’t allow for redeployment to other machines down the line. This also means paying for up-front development costs that companies offering standardized solutions like Flexxbotics have already figured out.

Do-It-Yourself Solutions

Do-it-yourself solutions often have the cheapest up-front cost since you don’t have to hire a 3rd party (at first). However, these initial cost savings often lead to extra opportunity costs over time. Moreover, project timelines may extend due to the need to learn on the fly. During this time, the production may not be running. On top of that, there are countless horror stories of end-users taking on a DIY robot project and making so many mistakes that they have to end up hiring an expert to finish the job. This can sometimes end up being the costliest option.

Off-the-Shelf CNC Automation Solutions

CNC automation specialists like Flexxbotics often have off-the-shelf standardized solutions for CNC machine tending projects. When DIY and integrator solutions can have long project timelines, off-the-shelf automation solutions are plug and play. Those solutions mean less uncertainty and frustration up-front than making different components work together.

The Flexx CNC is a perfect example of a ready-made solution for robot to CNC integrations. The Flexx CNC Interface eliminates the complex and timely integration effort needed for your Universal Robot to communicate with your CNC machines. The modular hardware and software allow you to use one kitted solution for any machine communication controller. You can easily interface your Universal Robot to a singular CNC machine or have the ability to redeploy your robot easily to multiple CNC machines.